Surface Mount Technology was developed in the 1960s. During the 1970s and 1980s a revolution in the automation industry was begun, which raised the demand for Surface Mount Technology Components for a better assembly process. Before Surface Mount Technology, electronic components came with wire leads that were not ideal for complex devices. Moreover, such components with wire leads, now commonly known as through-hole components, were making the PCB assembly process significantly slow and costly. These problems were resolved by Surface Mount Technology (SMT), which has opened the door for the invention of complex electronics like mobile phones, laptops, medical products, industrial controls and sensors, and many more.

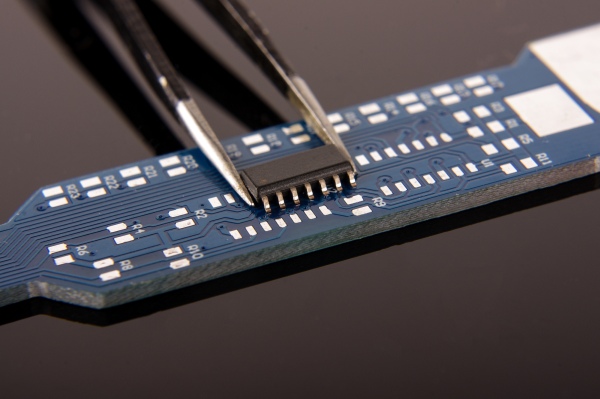

Surface Mounted Technology or “SMT” is used within the great majority of commercial electronics nowadays. The complex nature of SMT benefitted most applications of commercial electronics with the need to fit into very small spaces. To achieve this, components must be mounted directly onto the PCB surface as opposed to through-hole wire leads inserted into the board.

To say SMT was an important invention is an understatement. Electronic devices we have now would be much larger than they are. In fact, it’s safe to say that it’s a widely popular choice in today’s electronics. The reasons are many, including cost, size, simplicity of assembly and the amount of functionality demanded within a small volume. It’s these vital advantages that have seen SMT devices dominate the market. Here’s a rundown of some of the advantages afforded to surface-mounted technology devices.

Read more: WHAT IS SURFACE MOUNT TECHNOLOGY?