Summary of PWM DC Motor Speed Controller Circuit Using PIC16F877A Microcontroller

This article explains how to control the speed of a DC motor using Pulse Width Modulation (PWM) with a PIC16F877A microcontroller and an L293 motor driver IC. PWM regulates motor speed by varying the duty cycle of the pulses applied to the motor, providing efficient torque without power loss typical of using resistors. A Mikro C program is used to adjust the PWM duty cycle with two input switches, allowing speed increase or decrease. The project includes simulation in Proteus 8 and practical guidance for programming and testing.

Parts used in the PWM DC Motor Speed Control project:

- PIC16F877A Microcontroller

- L293 Motor Driver IC

- DC Motor

- Push-button switches (for duty cycle control)

- Proteus 8 Simulation Software (for virtual testing)

- USB PIC Programmer (for burning PIC microcontroller)

In our last PIC online tutorial we have covered PWM generation using PIC Microcontroller. As I told earlier PWM has wide application in electronics and robotics engineering.In this article I’m gonna show you one of the important applications of PWM in Robotics, it is called Pulse Width Modulation motor speed control.

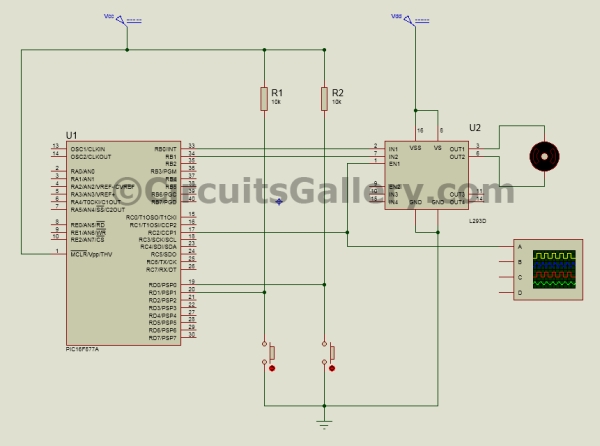

The method of generation of PWM signal is the same as before and this signal is applied to the Enable terminal of L293 motor driver IC. L293 is an H bridge motor controller IC capable of driving 2 Motor loads at a time.

Below is the detailed description of dc motor speed control using PWM technique with Proteus simulation and video demonstration.

Below is the detailed description of dc motor speed control using PWM technique with Proteus simulation and video demonstration.

Why We Need PWM For Speed Controlling Of DC Motor?

You may wonder why we need PWM signal for controlling DC motor speed when a resistor in series with the motor can simply do this job.

It’s because this method is not recommended in practical and also you don’t get enough torque to drive the motor with the help of resistor.

Limitation of using resistor

- DC motor needs more power during the operation, also it draws more current from the supply.

- If we use resistors, the motor will not get enough power to rotate because some of the power is dropped across the resistor (Low current).

- Also the current will be very low.

DC Motor Speed Control Using PWM Technique

DC Motor Speed Control Using PWM Technique

- With the help of PWM it is possible to control the average power delivered to a load and by thus we can easily regulate the speed of the DC Motor.

- When the width of pulse is high, the motor will rotate with full speed.

- Obviously with low pulse width, speed of motor gets reduced.

- In both cases full current reaches the motor and only the average power changes, thus we get better torque in each case.

- Basically in this method we are chopping the DC voltage at regular interval.

PWM DC Motor Speed Driver Schematic

PIC 16F877A PWM DC Motor Speed Control Mikro C Program

In this Mikro C embedded C program, two input switches are used to control the duty cycle of PWM signal.

S1 for increasing duty cycle and S2 for decreasing the same.

Frequency of PWM signal is set to 1 KHz

void main()

{

short duty1 = 16; //initial value for duty

TRISD = 0xFF; //PORTD as input

TRISC = 0x00; //PORTC as output

TRISB = 0x00; //PORTB as output

PORTB = 0x02; //Run motor in anticlock wise

PWM1_Init(1000); //Initialize PWM1

PWM1_Start(); //start PWM1

PWM1_Set_Duty(duty1); //Set current duty for PWM1

while (1) // endless loop

{

if (PORTD.F0==0) //Checking the button pressed or not

{

Delay_ms(1);

duty1++; // increment duty cycle

PWM1_Set_Duty(duty1); //Change the duty cycle

}

if (PORTD.F1==0) // Checking the button pressed or not

{

Delay_ms(1);

duty1–; // decrement duty cycle

PWM1_Set_Duty(duty1);

}

Delay_ms(10);

}

}

All the program codes are self-explanatory, if you have any doubts please let us know through the comment box below.

PIC PWM Motor Speed Control Simulation in Proteus 8

Let’s start our virtual lab!

Step 1:

Generate .Hex file for PWM speed control in Mikro C.

Compile the above program in Mikro C, if you don’t know how to build hex file please read our Getting started guide for Mikro C Pro.

Step 2:

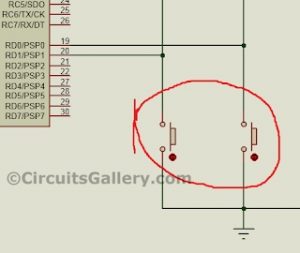

Draw the schematic in Proteus 8 as shown.

Step 3:

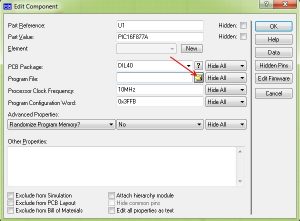

Load .Hex file to the PIC.

Practical help: Use our USB PIC Programmer circuit for burning PIC Microcontroller practically.

Step 4: Step 5:

Step 5:

Change duty cycle using provided keys and observe the speed of DC motor (watch the video).

Downloads: PWM DC Motor control .Hex file.

Circuits Gallery Video Lab

Watch this video from our Video lab where I have explained everything related to PIC PWM DC motor speed controller.

[Video will be uploaded soon…]

Please like our Facebook page to stay connected.

Next → Speed and Direction control of DC motor using PIC Microcontroller

For more detail: PWM DC Motor Speed Controller Circuit Using PIC16F877A Microcontroller