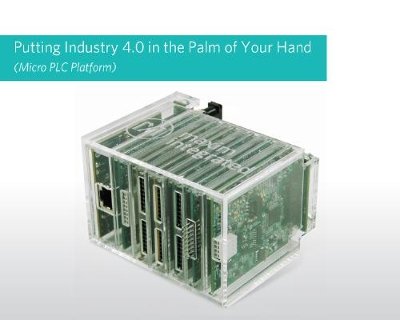

Maxim’s Micro PLC platform gives designers the tools to implement Industry 4.0 with less power, parts, and total costs.

The platform consists of five reference designs which can operate as stand-alone subsystems and be configured and tested with a laptop’s USB port.

A programmable logic controller (PLC) is the core building block that controls and coordinates sensors and machinery moving throughout a factory.

Each year, $800bn is spent on factory maintenance and lost productivity.

To reduce these expenses, the global Industry 4.0 movement is working to make manufacturing smarter and more efficient.

Through ‘smart integration’ (integration aligned with solving industry-wide issues) and proprietary process technology, Maxim’s Micro PLC platform claims to deliver a 10x reduction in form factor, > 50% power savings, and processes digital I/O outputs up to 70x faster than ever before. The platform will immediately reduce industry maintenance costs and increase uptime.

Supporting the Industry 4.0 distributed model, Maxim has developed multiple products that are interoperable with the Micro PLC platform:

MAX11270: a 24-bit, 10mW, delta-sigma ADC with integrated PGA offers the highest signal-to-noise (SNR) and lowest power in its class.

MAX17515: a 5A, 2.4V to 5.5V input, complete switch-mode power supply with built-in inductor that reduces energy loss and heat with 92% efficiency.

MAX17552: a 4V to 60V, 100mA, ultra-small, synchronous step-down DC-DC converter, compliant to IEC61131-2 PLC standard, that reduces heat dissipation and enables up to 50% cooler operation

Key Advantages are:

Faster throughput: up to 70x faster digital I/O provides increased production throughput

Power efficiency: > 50% power savings, allowing fan-less operations and higher density of I/Os.

For more detail: Maxim brings out Micro PLC platform