1. Quite a few POV clocks out there, why is this special?

Well, mainly because it’s mine. There are quite a few POV clocks out there on the web using all sorts of display mechanisms, chassis, controllers. The one I decided to build isn’t exactly one of them, the main difference being in the way I wanted to transfer energy to the spindle. This would add some originality to my project, sadly the method I chose was not working the way I expected it to. I can send the firmware in hex format to anyone who wants it, but since I started out with nothing: everyone who wishes to make the slightest modifications on it will have to write the code on his/her own. This is just my way to encourage learning. I am willing and happy to help, but against using code that isn’t fully understood.

2. Where POV can be used

A POV device can take several forms, in hobbyist electronics circles it’s mostly used at these type of clocks. Throughout the life of every determined hobbyist one day will come when she/he will eventually build such a device. Sometimes this day is windy and they end up with just a simple clock, not a POV clock – but that doesn’t matter. A clock is a good thing to build, many things can be learned, and the thing is useful anyway. The triggering idea (the unique PSU) proved to be wrong, but I intend to build another one, with cutom made enclosure, not an HDD chassis – this way I won’t have to deal with the impossible shapes the boards have to take!

While cleaning out my lab I have found some older (not that pretty) experiments with this, they never got finished. I remember building the first one with wires attached to the parallel port of a laptop. A pascal program was then written to blink the LEDs the way I wanted. It kinda worked, sorta worked, but never really-really worked. So the day I mentioned before came quite a few years ago, sadly I hadn’t got enough experience to accomplish what I wanted. This had to change :)!

1. What brought the old idea back to life

One day, when I was looking through the contests that got announced here, I found the “Remix contest“. I’ve always wanted to press the “I made it!” button, and this contest gave me the ambition to look for a great one, here on Instructables. The one I chose was the “Propeller clock (from an old HDD)“, It was a great project built very cool, but with lack of description about the build. I looked through the comments and saw a lot of people asking for code samples, schematics, unfortunately the builder “snarcis” didn’t had any time to refurbish the instructable. That’s why I’m going to do that myself, and present a step-by-step guide on how such devices can be built. The Remix contest is long closed, unfortunately.

I will try to make this one my best guide so far, to be careful and precise with pictures, instructions – so this can really become a winner.

I got this HDD from a good friend as a gift, I will consider giving it away as a gift to someone, maybe for Christmas, since there are only a few Fridays until then anyway!

That being said, let’s see how can one build such a cool, tech looking device!

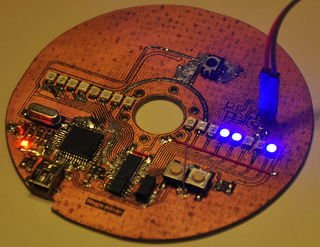

1. Bill of materials – must have

As usual, the first step is the one that lets you know what you need before you get started. I might have forgot about tools or components, however the main parts are surely there.

- 1 x Unusable computer hard disk

- 2 x PIC18F4550 microprocessor IC

- 1 x PCF8523 real time clock and calendar IC

- 1 x PCA9635 sixteen channel LED driver IC

- 1 x PicKit2, PicKit3 or any PIC programmer

- 1 x 32.768 KHz crystal oscillator for the real time clock

- 1 x 20.000 MHz crystal oscillator for the microprocessor

- 16 x LED of whatever color you wish

- 1 x infrared LED

- 1 x photodiode

- 4 x buttons

- 6 x N-channel MOSFET for the brushless motor drive

- n x capacitors as specified in the schematic

- n x resistors as specified in the schematic

- n x hand tools, screw drivers, saw, pile, hammer, drill, soldering iron

There are lots of places where you can purchase these components from, I got some off ebay, some from my drawers, some were taken off junk PCB-s I got from all over.

2. Extra stuff I had at hand that helped a lot

I’ve had these excellent tools at hand to ease my job:

- RIGOL DS1104Z Oscilloscope – my best investment ever

- Multimeter – an electronic hobbyist can’t do anything without a multimeter, right?

- Programmer – PicKit2, PicKit3 or anything that does the job

- Scanalogic 2 logic analyzer – second best investment ever, even though the oscilloscope has I²C, SPI and other decoders, I like this blue box better when it comes to analyzing some fancy serial protocols.

- Organizers – I have to mention this because I was able to find everything I looked for almost instantly. I’m really glad I bought these, they replaced some boxes which I used for storage in a very sad and inefficient way.

- Power supply – I bought it last year as a Christmas present to myself. 30V, 3A, great for my projects.

- Power supply – I described this build in another instructable, it’s a self built device to aid me with six (switched mode) power source.

- Patience – even though I don’t happen to have that much sometimes

- Ambition – looking at the fact that I made a total number of four circle shaped PCBs, I dare to say my ambition was all right. Hopefully I will be able to start up my CNC mill real soon so from now on this and the drilling will be much easier. Piling and sawing shapes like this is no fun, especially if you do it four times 🙂

These are good to have, I am proud and happy to say that I managed to buy these myself – aside of the multimeter, which I got from Dad. Most of my tools have a sticker on them to make sure they don’t get lost, you can see that on many of them.

For more detail: HDD Clock – Persistence of Vision