The aim of this project is synchronization of multiple motors using wireless technology. This project uses radio frequency to synchronize motor speeds. This is applicable to many industries like textile mills, steel plants, and paper plants wherein all the motors used on conveyor are desired to be synchronized.

For example, in textile mills where multiple motors work simultaneously on a conveyor belt to draw clothes, it is essential that all the motors there should run at same speed, so that balanced tension is achieved to avoid clothes getting damaged. In this project motors are wirelessly synchronized to make the differential speed error among multiple motors to zero.

For example, in textile mills where multiple motors work simultaneously on a conveyor belt to draw clothes, it is essential that all the motors there should run at same speed, so that balanced tension is achieved to avoid clothes getting damaged. In this project motors are wirelessly synchronized to make the differential speed error among multiple motors to zero.

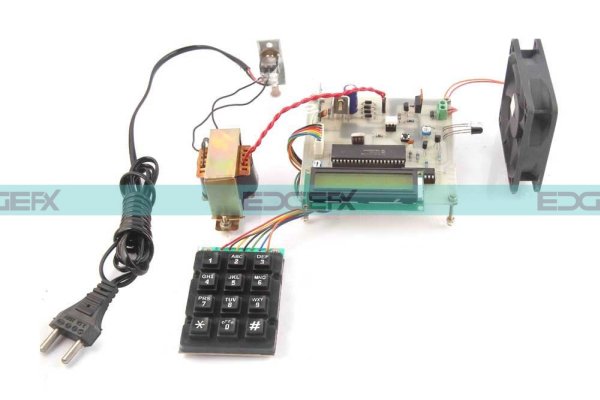

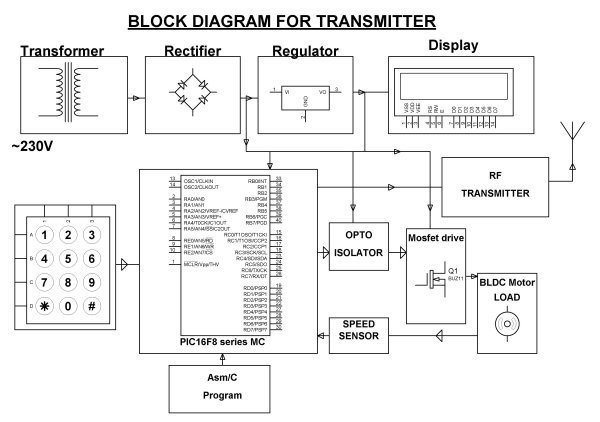

One motor acts as transmitter and all the rest as receivers. Thus, if a particular speed is set in the transmitter then all other motors speed would be matched to the same speed of the main motor. The mode of communication is radio frequency. BLDC motors used operate on the basis of PWM control.

Each motor has a closed loop feedback mechanism providing RPM reference by a shaft mounted IR sensor arrangement whose output is fed to the controller in the circuit. A display unit displays the full speed and one can enter the desired percentage with help of a keypad to obtain the required speed for all the motors.

The pulse width output from the microcontroller would be automatically adjusted to maintain the DC power to the motor such that the entered speed percentage matches the running RPM. The above operation is carried out by using one opto isolator and a MOSFET for driving the BLDC motor duly interfaced from the microcontroller.

The pulse width output from the microcontroller would be automatically adjusted to maintain the DC power to the motor such that the entered speed percentage matches the running RPM. The above operation is carried out by using one opto isolator and a MOSFET for driving the BLDC motor duly interfaced from the microcontroller.

For more detail: Speed Synchronization of Multiple Motors In Industries using PIC Microcontroller