Summary of Dspic-Servo Project using PIC30F4012 microcontroller

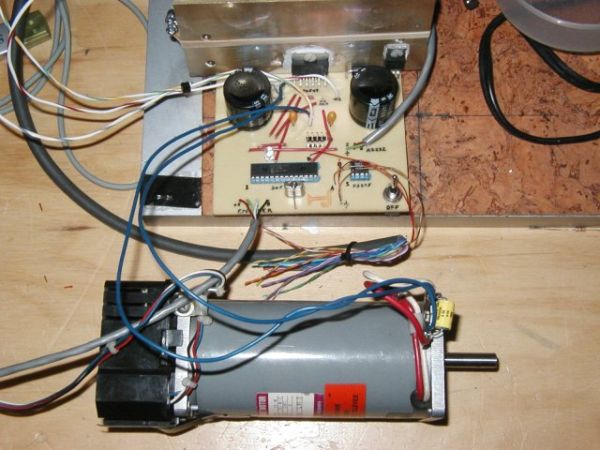

This project presents a cost-effective drive board for small DC brushed motors configured as positioning servos for desktop CNC machines. It uses quadrature drive signals via a PC’s parallel port and features a power op amp operating in constant current mode. A Microchip PIC30F4012 microcontroller controls the servo loop, which is tuned via a serial port at 9600 baud. Parameters like PID gains, deadband, max current, and fault error are adjustable and stored in EEPROM, optimizing motor control and fault detection. The setup ensures precise position tracking by maintaining commanded and actual encoder counts closely matched.

Parts used in the Dspic-Servo Project:

- Microchip PIC30F4012 microcontroller

- Power operational amplifier (power op amp)

- EEPROM (internal to PIC30F4012)

- Serial interface (for tuning parameters)

- Parallel port connection (2 pins for quadrature drive)

- DC brushed motor (small size for CNC application)

Project Description

This project was developed as an inexpensive way to drive small dc brushed motors as positioning servos for use on a desktop sized CNC machine. The board is interfaced to the PC through 2 pins of a parallel port. The drive signal on these pins is known as quadrature drive.

The power stage consists of a power op amp driven in constant current mode. The internal PIC processor ( a 30f4012 from Microchip ) is programmed in C through the C30 compiler and the Microchip IDE. The servo loop parameters are programmed through a serial port connection and are saved in the dspic eeprom. Once set for a particular drive, they should not need to be changed.

A YouTube video by Ted Maczulat.

The serial programming interface is used to tune the PID and other servo loop parameters to optimize the performance in a particular application. The serial port runs at a fixed baud rate of 9600N81. Any terminal program such as minicom, gtkterm, or hyperterminal may be used to talk to the dspic-servo. On powerup you will see the following:

Powerup...i/o...uart...timer...pwm...pid...encoder...capture...done dspic-servo by L. Glaister (c)25-Sept-2006 by VE7IT using setup from eeprom.. ? for help Current Settings: servo enabled = 1 (p) = 0.020000 (i) = 0.000000 (d) = 0.000050 FF(0) = 0.000000 FF(1) = 0.000000 dead(b)and = 1.000000 (m)ax output = 2.500000 (f)ault error = 1024.000000 (x)pc cmd multiplier = 3 (t)icks per servo cycle= 10

To change a value, type the cmd letter/number and then a value for example:

p0.03

The current values will be redisplayed with the new value set. The p,i,d, ff0 and ff1 values are standard loop gain parameters. You can reference the source code for a better explanation. The deadband parameter is the number of encoder counts the servo can be out of position without the servo loop taking any corrective action. The max output is the maximum current output allowed in amps and should be set for the particular motor you are using. This number can be up to 7 amps. The fault error parameter is used to set the number of counts the servo can be out of position before the drive gives up and indicates a drive fault. This is used to detect crashes and jammed axis or input command conditions beyound the capabilities of the motor. The pc command multiplier is useful for cases where you have a high resolution encoder on the motor and a PC that is limited in the number of pulses/second it can output. For most operation this number will be set to 1, but if you have trouble reaching the top speed you need from the drive, it may be helpful to set this number to a higher value. The internal servo loop works by keeping 2 counters. The first is the commanded position from the PC, the second is the actual position from the encoder. The servo loop of the drive attempts to keep these 2 numbers as close as possible to each other.

For more detail: Dspic-Servo Project using PIC30F4012 microcontroller