Description

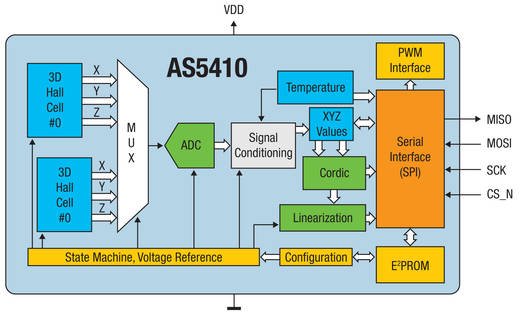

The AS5410 allows absolute position sensing of a simple two-pole magnet immediately after starting up the device without the need for a prior reference run within the application. Position sensing is possible over large mechanical travel distances even with very small magnets: a travel distance of 40mm does not pose a problem for a small, 4 x 4 x 3 mm sized NeFeB magnet, for example. Moreover, the 3D Hall solution’s output remains stable even when the device is subject to external stray magnetic fields. This feature is a worldwide first and the result of a special differential measurement technique including several 3D Hall sensor elements. Programming the internal EEPROM of the AS5410 allows to convert a wide range of geometries including curved movements, non-linear scales, and tilted chip/magnet geometries into a linear output signal. In order to achieve a perfectly linearized output (up to 0.5% accuracy), the AS5410 linear position sensor provides an internal linearization table with 33 base points. With four preset basic operating modes which are selectable via SPI, the ams AS5410 3D Hall position sensor (previously known as encoder) offers quick and easy configuration. All signal conditioning is on chip, including compensation for temperature effects.

The AS5410 is available in a 14-pin TSSOP package as well as and is qualified for an ambient temperature range from -40°C to +105°C. It operates at a supply voltage of 3.3V +/-10%

Key Features

- Absolute position sensing of 3D magnet trajectories

- Insensitive to external magnetic stray fields (differential principle)

- Up to 14-bit full scale resolution

- 33 point linearization

- Programmable output characteristic

- Configurable threshold position switch

- SPI and PWM output

- Re-configurable E²PROM on-chip

Applications

- Automotive pedal absolute position measurement

- Plunger absolute position measurement

- HVAC flap absolute position measurement

- Absolute position measurement of various trajectories up to 50 mm movement range

- Extended range (> 50 mm) through cascading of several AS5410s

Austriamicrosystems has introduced its first linear position sensor based on its 3D Hall platform.

The 3D Hall sensor architecture was developed in co-operation with Fraunhofer Institute for Integrated Circuits IIS in Germany using patented technology called HallinOne.

“The strength of this technology is the true 3D measurement of magnetic field components,” said Marcel Urban, product manager magnetic encoders at austriamicrosystems.

“Accurately calibrated lateral and vertical Hall sensors are used to increase the overall performance. By using two 3D pixels cells in a differential measurement approach, the absolute linear position measurement range is extended to 40mm,” said Urban.

This first device, the AS5410 can be used to provide absolute position sensing of a two-pole magnet immediately after starting up the device without the need for a prior reference run within the application, said the supplier.

Position sensing is possible over large mechanical travel distances even with very small magnets: a travel distance of 40mm does not pose a problem for a small, 4 x 4 x 3 mm sized NeFeB magnet, for example.

A feature of the 3D Hall design is that the output remains stable even when the device is subject to external stray magnetic fields.

For more read: Chip firm puts 3D sensing devices technology into first