This project described the second part of the following project:

- An RF Thermostat as described in the following Instructurable: https://www.instructables.com/id/RF-Thermostat/

- An RF Panel Relay, described in this Instructable

For an introduction on this project first read the description of the RF Thermostat.

In short the RF Panel Relay has the following functions:

- Decode an RF message received via an 433 MHz RF link according to the protocol described in the RF Thermostat Instructable

- Control a relay based on the contents of the received RF message

- Switch off the relay if no RF message is received after a certain time frame

As always I used a PIC microcontroller and created all software without using any specific libraries. Arduino fans can use of course do the same.

Step 1: Required Components

You need to have the following components for this project:

- A piece of breadboard

- PIC microcontroller 12F615

- 433 MHz RF receiver, like the SRX882 433MHz ASK Superhetrodyne receiver

- Fuse holder + fuse 6,3A/250V

- 2 * 100nF ceramic capacitor

- 1 * 33k, 1 * 220 Ohm, 1 * 180 Ohm, 1 * 1k resistors

- 1 * red LED, 1 * green LED

- Diode 1N4148

- BC640 transistor

- Relays operating on +5 Volt and capable of switch sufficient mains power. I used: https://www.aliexpress.com/item/5pcs-SRD-05VDC-SL-C-5VDC-10A-Power-relay-PCB-Type-T73-5V-5-feet-SRD/32653259475.html?spm=2114.13010608.0.0.l3L3LV

- 5 Volt Power supply sufficient to power the circuit. I used: https://www.aliexpress.com/item/5V-700mA-3-5W-AC-DC-Precision-Buck-Converter-AC-220v-to-5v-DC-step-down/32649591757.html?spm=2114.13010608.0.0.wsZU1q

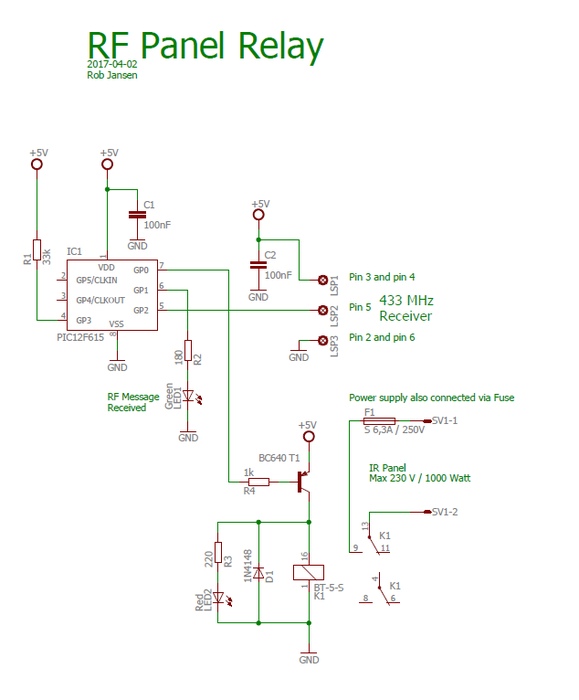

See the schematic diagram on how to connect the components.

Step 2: Building the Electronics

You can build the circuit on a breadboard but be very careful with the Fuse and the Relays that switch the mains power for the Infra-Red Panel. Do not touch the mains power in any way!

In the picture you can see the circuit as I build it on the breadboard. The whole circuit was built as to fit in a welding box.

Step 3: The Software

As already mentioned, the software is written for a PIC12F615. It was written in JAL. Since I did not use any specific libraries the total code size is 445 bytes which fits nicely in the 1k program flash memory this specific controller has.

The software performs the following main tasks:

- Decoding the RF messages. For this it uses a capture timer that captures the duration of the bits. The decoding routine works completely interrupt based and uses each bit level change of the Manchester encoded RF message by constantly changing the interrupt edge level. This increases the reliability of the decoding routine

- Switch on the relay when the ‘on’ command is received or switch the relay off when the ‘off’ command is received

- Switch off the relay when no more messages are received for a period of 10 minutes. As mentioned in the Instructable of the RF Thermostat, the RF message is repeated every 2 minutes to keep the connection ‘alive’. If for some reason the relay is switched on but the RF Thermostat is switched off without having sent an ‘off’ command, the software will always switch off the relay after 10 minutes

- Kicking the watch dog on a frequent basis. The watchdog will not reset the controller if it is triggered each 18 ms. The main program uses a loop time of 1 ms in which it kicks the watchdog and so prevents the dog from barking. The watchdog is used to prevent any hang-ups in the software and in case a hang-up should happen, the program is reset and the relay is switched off

The PIC controller runs on an internal clock with a frequency of 8 MHz. The Intel Hex file is attached.

The video shows the final set-up with the RF Thermostat in a housing and the RF Panel Relay in the welding box with cover. It demonstrates switching the RF Thermostat on and switching the RF Panel Relay on by increasing the desired temperature on the RF Thermostat. On the RF Panel Relay the green LED indicates that a valid message was received where the red LED indicates that the relay – and so the Infra Red panel – is switched on.

Have fun building your own project and looking forward to your reactions.

Attachments

Source: RF Panel Relay