Ultra low cost solar-rechargeable persistence of vision display

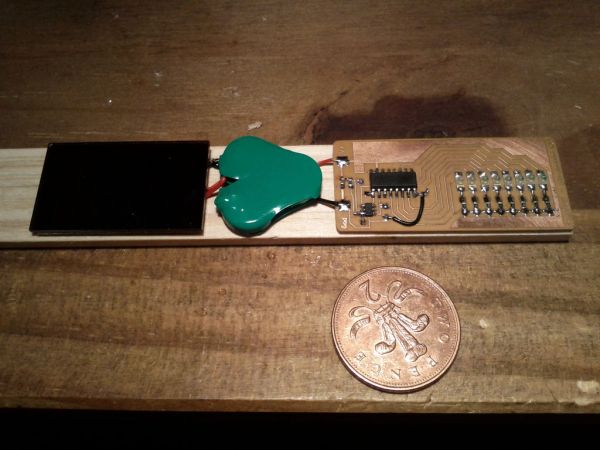

This device produces a bright and eye catching display to write text and small images through the air. It uses under £2 (approx $3.20 US at the time of writing) of parts, and is a nice little weekend project to impress your friends and family.

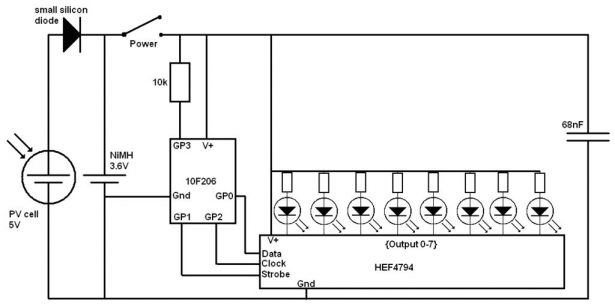

It uses the PIC10F206 from microchip, the tiniest microcontroller I have ever seen. Its advantages are that its small, fast and reliable and has a built in RC clock so there is no need to mess around with crystals and resonators. Its downside is that it only has 6 pins, 2 of which are taken up by power and ground! The way to get around this is to use shift registers to give yourself more outputs as you will see in the next few pages.

It also uses a small rechargeable battery and solar cell, which are typically pricey items, but currently there is a huge flood of keyring-sized cheap solar powered torches from china, which can be bought from the pound shop in England, or had very cheaply on eBay. I have even seen these for sale in petrol stations.

You will need:

Materials:

A solar powered keyring torch

A ‘wooden plant label’ or other suitable handle.

Small scraps of wire

HEF4794 shift register in an SOIC package

10F206 in an SOT23-6 package

8x Surface mount LEDs of your choice – I used blue in 1206 package

8x Resistors of your choice – I used 320 ohms in 0603 package

1x 10k resistor in an 0603 package

1x 68nF capacitor in an 003 package

Copper-clad board

Tools:

A drill or veroboard cutter

Needle file (or some method of making square holes)

Soldering iron with a fine tip, preferably temperature controlled

Thin solder

Desoldering braid or a way to remove excess solder from the torch PCB

Tweezers for placing small components

Glue gun or double sided tape

PIC programmer that supports PIC10F206 – I used the PICKIT2

Optional:

Flux

Hot air soldering station

Method of producing PCBs

Cleaning alcohol -methylated spirit or isopropanol will do

Carefully dissect the torch

A sharp screwdriver helps to get into the gap and separate the 2 halves of the casing as shown below. The casing just pushes together – there are no screws.

Prepare the torch parts

You can also desolder the LEDs from the board, using the solder braid to ensure there are no blobs of solder sticking up, though bare in mind the link wires from the PCB to the panel are extremely fragile.Safety note: If you are soldering for more than a few seconds in the same spot, it may be wise to stop and let the board cool down. The heat can pass through the board and in theory cause the glass in the panel to expand and crack, though I didn’t have this problem with mine.