Aiming at lighting manufacturers that don’t want to buy a soldering line, Sheffield-based Litecool has developed a self-adhesive self-connecting LED package that can be pick-and-placed direct onto heatsinks – and it accepts standard lenses from Carclo.

No PCB, metal-cored or otherwise, is required.

The key to self-adhesive packaging for power devices is to spread heat to an area much large than the die before it reaches the self-adhesive bond which, even with high-performance thermal adhesive, adds resistance to heat flow. Litecool’s speciality is thermal design. Previous products have included a 10,000 lm high-bay luminaire weighing 2.5kg, and a 1,000 lm spotlight weighing 142g, both including heatsink.

Litecool’s speciality is thermal design. Previous products have included a 10,000 lm high-bay luminaire weighing 2.5kg, and a 1,000 lm spotlight weighing 142g, both including heatsink.

“Instead of trying to reduce the thermal resistance of an individual component in a system we ask ourselves why these components were in the system at all. By removing the circuit board form the system we can optimise cost and performance,” said Litecool chief packaging engineer Elwyn Wakefield.

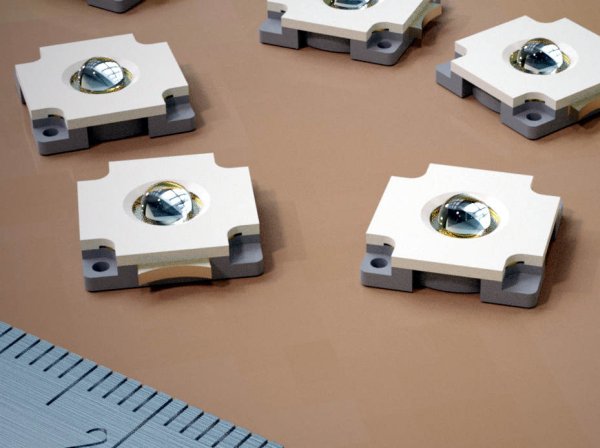

Its package, called Lumen Block and initially designed for 1mm die, and has a 7.5mm diameter thermal contact area – a 44:1 spread before the adhesive layer.

“The die directly on a heatsink would not be as good as in our package because we have spread the heat,” company CEO James Reeves told Electronics Weekly.

Litecool will use conventional solder or resin to bond LED die into the package, then wire-bond to the packages’ internal connector frame for electrical continuity.

Each of the four edges of Lumen Block has a connector: one male and three female, allowing series chains of arbitrary length to snake around in any Cartesian pattern.

Female connectors are open at the bottom, allowing one to be placed over a previously-placed male connector in sequence. The female part is springy to get contact, and both types of connector are soft gold plated.

For more detail: Solder-free pick-and-place package for LED lighting