Choosing components is a series of time-consuming tasks, from surveying the market for possible candidates to properly evaluating performance. As a hardware engineer who has worked in Silicon Valley for 10 years, I have spent significant time developing test plans and specs, building fixtures, and testing components. One of the reasons comparing components takes a long time is because you can’t always rely on datasheets to give you the information you need. The problem with datasheets is that they only tell you the story the vendor of the component wants. If an IC characteristic is better under specific conditions, you can be sure the vendor will showcase their components under those conditions.

For example, a digital MEMS microphone’s current consumption is directly related to input clock rate, which also affects Signal-to-Noise Ratio (SNR), among other performance characteristics. So one vendor may specify current consumption using a minimum functional clock rate, and SNR using a higher one, while another vendor may use a single clock rate for both. This type of inconsistency makes it difficult to compare across vendors based on datasheets alone. Instead, I need to get samples from as many vendors as I can and test them all myself. Acquiring the samples is a lengthy process, and in most cases, I can only evaluate a small subset of components that are available in the market before making a decision.

After going through this process repeatedly, I decided to create a more efficient solution for myself and fellow hardware engineers. I teamed up with my former colleague, Yaneeka Huq, to build GPiO. We started the site with 60+ analog, digital, ECM (electret condenser microphone), and MEMS microphones from leading vendors, creating the leading resource for microphone performance data. This data, measured in our own lab, includes sensitivity, frequency response, SNR (and equivalent input noise), Total Harmonic Distortion (THD) vs. level, current consumption, power supply rejection, and more.

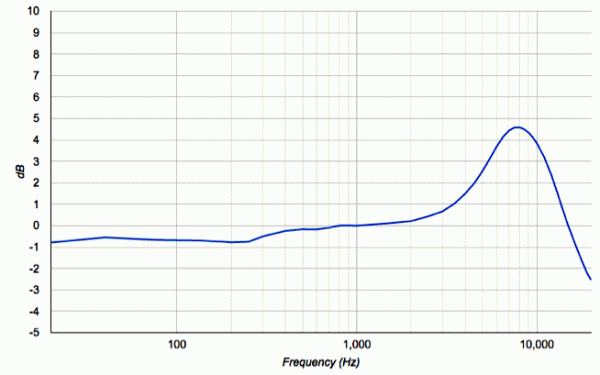

Close examination of our measurements reveals some interesting distinctions among the microphones available on the market. In their intended bandwidth, microphones generally have larger variations in frequency response than purely electrical components, such as power amplifiers. However, many people think of microphones as having very flat frequency responses. Our data shows that this is not generally true for small ECMs and MEMS microphones. For example, Figure 1 shows our data for a microphone with a frequency response that starts to roll off around 600Hz. This type of roll-off can be useful in reducing wind noise, but may be undesirable otherwise. Figure 2 shows our data for a microphone where the trapped volume in front of the diaphragm (within its package) creates a resonance around 8kHz. Our range of hearing extends to 20kHz, so this microphone is more appropriate for narrowband telephony rather than wideband recordings.

For more detail: Site enables detailed component comparisons