Being an active outdoor guy, I have a few different types of 12V lights and a variety of battery types.

– For flying RC planes and quadcopters at night, we use sealed lead acid batteries to power our club tables.

– For fishing, I have a few 12V 2W led lights, powered by 2200mA, 3 cell LiPo batteries.

– For camping, the tent and trailer lights are using 12V sealed lead acid batteries, and portable lights 2200mA 3 cell LiPo batteries.

As I do not want to totally discharge any of my batteries, I decided to design this battery monitor.

Features needed:

– Easy to use and install permanently.

– To be able to use on any battery type used for 12V lights.

– Non-irritating alarm.

– Adjustable alarm pick-up value.

Instead of setting the alarm value using a pot, I opted for an easy programmable option, thus the need for a microcontroller (PIC 12F675).

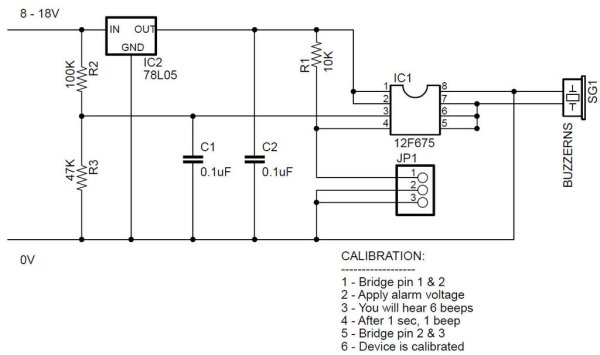

The 12F675 is powered via the 78L05 regulator, and this voltage is also the A/D converter reference voltage. Using a resistor voltage divider (R2 & R3), the battery voltage is measured using the internal A/D converter of the 12F675.. This divider values were chosen such that the maximum measurable voltage of the 12F675 will be around 15V, with a resolution of around 15mV.

The buzzer is a standard 5V piezo buzzer, and will give 3 short beeps ever 15 seconds once the battery voltage is below the alarm value.

Programming of the alarm level is obtained with a 3-pin header and mini jumper.

Specifications:

Maximum input voltage 20V

Minimum input voltage 8V

Minimum alarm voltage level 8V

Maximum alarm voltage level 15V

Idle current 3.12mA

Alarm voltage resolution 15mV

Step 1: Building the Battery Monitor

You will need the following components:

R1 10K resistor

R2 100K, 1% resistor

R3 47K, 1% resistor

C1, C2 0.1uf capacitors

IC1 Microchip PIC 12F675

IC2 78L05 voltage regulator

SG1 5V piezo buzzer

JP1 3 pin header, with mini jumper

Build the circuit using veroboard or PC Board.

Step 2: Using PC Board

As I wanted to build a couple of this Battery Monitors, I opted to make a couple of PC boards. Using the free version of Eagle, I was able to make 12 boards at once on the 100 x 80 PC Board.

However, the circuit is easy enough to build on a piece of strip board.

Step 3: Assembly

Using the PC Boards, assembly took only a few minutes per board. After testing the circuit, I used heat shrink to cover the project to keep costs down.

PLEASE NOTE:

The PIC 12F675 needs to be programmed first. Please upload this HEX file first before soldering on the 12F675, or use an IC socket.

For more detail: PIC 12F675 Programmable 12V Battery Monitor