Summary of HUMANOID robotic ARM using pic microcontroller

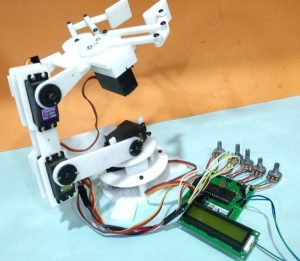

This article discusses building a robotic arm controlled by a PIC16F877A microcontroller using potentiometers to generate PWM signals for servo motors. The PIC's limited PWM pins necessitate software PWM generation via timer interrupts to manage five servos. The arm's mechanical parts are 3D printed, powered by dual 7805 voltage regulators to prevent voltage drops during servo operation. The system includes a 16x2 LCD for display and programming support via ICSP. The tutorial covers circuit design, PWM signal generation, and mapping potentiometer input to servo positions, offering a cost-effective alternative to advanced microcontrollers for learning purposes.

Parts used in the HUMANOID robotic ARM using pic microcontroller:

- PIC16F877A microcontroller

- Five hobby servo motors

- Potentiometers (5 pieces)

- 12V power adapter

- Two 7805 voltage regulators

- 16x2 LCD display

- 3D printed robotic arm mechanical structure

- Various GPIO pins connection headers

- Pickit3 programmer (for ICSP programming)

From the assembly line of automobile manufacturing industries to the telesurgery robots in space, Robotic Arms are to be found everywhere. The mechanisms of these robots are similar to a human which can be programmed for similar function and increased capabilities. They can be used to perform repeated actions faster and accurate than humans or can be used in harsh environments without risking human life. We have already built a Record and Play Robotic Arm using Arduino which could be trained to do a particular task and made to repeat forever.

In this tutorial, we will use the industry standard PIC16F877A 8-bit Microcontroller to control the same robotic arm with potentiometers. The challenge with this project is that PIC16F877A has only two PWN capable pins, but we need to control about 5 servo motors for our robot which requires 5 individual PWM pins. So we have to utilize the GPIO pins and generate PWM signals on PIC GPIO pins using the timer interrupts. Now, of course, we could upgrade to a better microcontroller or use a de-multiplexer IC to make things a lot easier here. But still, it is worth giving this project a try for the learning experience.

The mechanical structure of the robotic arm that I am using in this project was completely 3D printed for my previous project; you can find the complete design files and assembling procedure here. Alternatively, if you do not have a 3D printer you can also build a simple Robotic Arm using cardboards as show in the link. Assuming that you have somehow got hold of your robotic Arm lets proceed into the project.

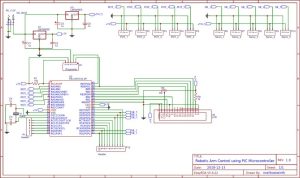

Step 1: Circuit Diagram

The Complete circuit diagram for this PIC Microcontroller based Robotic Arm is shown below. The schematics was drawn using EasyEDA.

The circuit diagram is pretty simple; the complete project is powered by the 12V adapter. This 12V is then converted to +5V using two 7805 Voltage regulators. One is labeled as +5V and the other is labeled as +5V(2). The reason for having two regulators is that when the servo rotates it pulls in a lot of current which creates a voltage drop. This voltage drop forces the PIC to restart itself, hence we cannot operate both the PIC and the servo motors on the same +5V rail. So the one labeled as +5V is used to power the PIC Microcontroller, LCD and Potentiometers and a separate regulator output which is labeled as +5V(2) is used to power the servo motors.

The five output pins of the potentiometers which provide a variable voltage from 0V to 5V are connected to the analog pins An0 to AN4 of the PIC. Since we are planning to use timers to generate PWM the servo motors can be connected to any GPIO pin. I have selected pins form RD2 to RD6 for the servo motors, but it can be any GPIO of your choice.

Since the program involves a lot of debugging, a 16×2 LCD display is also interfaced to portB of the PIC. This will display the duty cycle of the servo motors that are being controlled. Apart from this I have also extended connections for all GPIO and analog pins, just in case if any sensors need to be interfaced in future. Finally I have also connected the programmer pin H1 to directly program the PIC with pickit3 using the ICSP programming option.

Step 2: Generating PWM Signals on GPIO Pin for Servo Motor Control

Once the circuit is ready we have to figure out how to generate PWN signals on the GPIO pin of PIC to control the servo motor. We have already tired something similar using the Timer interrupt method and were successful. Here we are just going to build on top of it.

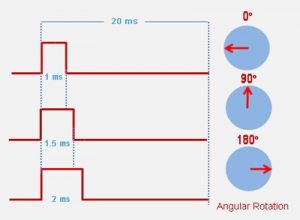

All hobby servo motors work with a frequency of 50Hz. Meaning one complete pulse cycle for a servo motor will be 1/50 (F=1/T) which is 20ms. Of this complete 20ms the control signal is only from 0 to 2ms while the rest of the signal is always off. The below figure shows how the ON time varies only from 0 to 2ms to rotate the motor from 0 degree to 180 degree of the total 20ms duration.

With this in mind we have to write the program in such a way that the PIC reads in 0 to1204 from the potentiometer and maps it to 0 to 100 which will be the duty cycle of the servo motor. Using this duty cycle we can calculate the ON time of the servo motor. Then we can initialize the timer interrupt to overflow at a regular interval such that it acts similar to the millis() function in Arduino. With that, we can toggle the status GPIO pin to be high for a desired duration and turn it off after 20ms (one complete cycle) and then repeat the same process. Now, that we have understood the logic let us get into the program.