For circuits relying on lithium-ion cells, determining the amount of charge remaining in a cell requires specialized techniques that can complicate the design of energy-harvesting applications. Engineers can implement these techniques with MCUs and ADCs normally used in these applications, but at the cost of increased complexity. Instead, engineers can easily add this functionality to existing designs using dedicated “fuel-gauge” ICs available from manufacturers including Linear Technology, Maxim Integrated, STMicroelectronics, and Texas Instruments.

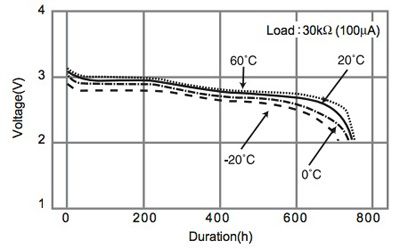

Determining the state of charge (SOC) in lithium-ion batteries is essential yet challenging due to the great variability in capacity not only across different cells, but also in the same cell. As a Li-ion cell ages, it loses its ability to store charge. Consequently, even if fully charged, an older cell would deliver usable voltage for a shorter period of time than a newer cell. With any Li-ion cell, SOC varies greatly depending on the temperature and discharge rate, resulting in a unique family of curves for any particular cell (Figure 1).

Figure 1: Output voltage for lithium-ion storage devices such as the Panasonic VL series depends on a number of factors, including temperature, discharge rate, and cell age (Courtesy of Panasonic).

Figure 1: Output voltage for lithium-ion storage devices such as the Panasonic VL series depends on a number of factors, including temperature, discharge rate, and cell age (Courtesy of Panasonic).

The nature of the characteristic output voltage curve for Li-ion technology complicates determining SOC. With other technologies, open-circuit voltage (OCV) offers a reliable indicator of state of charge. With Li-ion cells such as the Panasonic VI series, however, the relatively-flat voltage output curve found with these cells makes this method more challenging (Figure 1). Instead, Li-ion battery-monitoring methods typically rely on coulomb counting or impedance measurement; the former tracking the amount of current discharged over time, while the latter exploits the relationship between SOC and internal impedance of a cell.

Each of these methods requires careful and continuous measurement of battery output current and voltage, followed by careful analysis of those values compared to models that relate voltage to SOC. For energy-harvesting applications, engineers can often take advantage of MCUs and ADCs, devices already in place to provide core functionality for the energy-harvesting application. An ADC such as the Microchip Technology MCP3421 can be used to capture measurements of current and voltage output for analysis by the MCU (Figure 2). In turn, the MCU executes SOC algorithms or compares measured values with ideal values in an SOC lookup table, or relies on some combination of algorithmic analysis and data lookup.

For more detail: Fuel-Gauge ICs Simplify Li-Ion Cell Charge Monitoring