Abstract: Temperature-based fan control is a necessity in a growing number of systems, both to reduce system noise and to improve fan reliability. When fan control is augmented by fan-speed monitoring, a speed-control loop can be implemented that is independent of manufacturing variances and wear on the fan. In addition, a fan that is about to fail can be identified so that it can be replaced before it fails. This document discusses the operation of the MAX6650 and MAX6651, two fan controllers with linear closed loop fan speed control.

A similar version of this article appeared in the September 28, 2000 issue of EDN.

Introduction

As IC designers strive to put more transistors running at higher speeds into smaller packages, there can be only one outcome: heat! Couple this with the fact that these high-power ICs are being designed into ever-shrinking boxes, and you end up with a real thermal management problem. For many applications, this means using fans. Unfortunately with fan use comes the usual fan headaches of mechanical failures, increased power consumption, and more noise. Fan speed control and monitoring can ease

some of these headaches, resulting in quieter, more reliable fans that use less power.

Brushless DC Fans

Before we get into the subject of regulating and monitoring fans, we first need to understand the fans themselves. Brushless DC fans tend to be the solution of choice for most electronic enclosures. These fans couple high reliability with ease of use. The basic DC brushless fan is a 2-wire device over which a DC voltage is applied. That is all it takes. The simplest approach to system cooling is to connect a fan to a DC power supply and let it run. A quick glance at fan catalogs reveals that fans operating at a nominal 5V, 12V, 24V, or 48V are available. Currently, 12V fans seem to be the most widely used. As more systems are designed without a 12V power supply, 5V fans will likely become more prevalent. In telecom applications, 48V fans are especially popular.

Brushless DC fans are called “brushless” because the electric motor within the fan is commutated electronically. Older DC fans used mechanical brushes, which can cause increased electromagnetic

interference (EMI) along with dust particles due to mechanical wear throughout the system. Over time, the fan would wear and eventually fail. Brushless fans have replaced these mechanical brushes with electronic sensors and switches that now perform the necessary computation. This commutation circuitry

is mounted within the fan itself and is totally transparent to the user. The end result is a simple-to-use, 2-wire device. This has greatly increased the lifetime and the reliability of these fans.

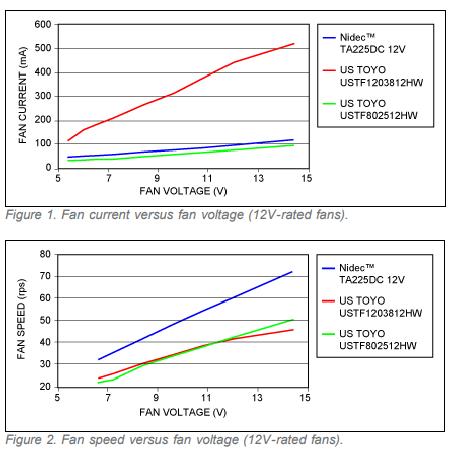

To the end user, DC brushless fans are fairly simple to characterize electrically.

Fan-Monitoring Options

Although brushless commutation has gone a long way in increasing the lifetime and the reliability of fans, they are still mechanical devices and prone to mechanical wear and failure. Over time, fan speed and therefore cooling efficiency can slowly degrade or fail completely. This is why it can be important to continuously monitor the condition of the fan. Most fan manufacturers offer a variety of ways to do this. These options fall into roughly two categories: alarm sensors and speed sensors.

Read More: Fan Speed Control Is Cool!