Summary of Real-Time CAN-Based Vehicle Monitoring System with PIC MCU

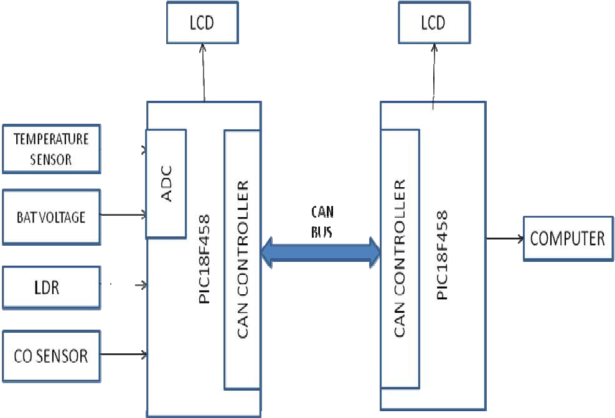

This project develops a vehicle monitoring system using the Controller Area Network (CAN) protocol for real-time data communication between nodes in a vehicle. It employs PIC18F458 microcontrollers with built-in CAN modules, MCP2551 transceivers, various sensors (temperature, gas, light, battery voltage), and a 16x2 LCD for display. The system consists of engine and dashboard nodes exchanging sensor data over CAN bus, validated through simulation and hardware tests. The design showcases robust, reliable vehicle parameter monitoring, with future improvements suggested in sensor range, error correction, interface flexibility, and integration with automotive-grade components for broader application.

Parts used in the CAN-Based Vehicle Monitoring System:

- PIC18F458 Microcontroller

- MCP2551 CAN Transceiver

- LM7805 Voltage Regulator

- LM35 Temperature Sensor

- Light Dependent Resistor (LDR)

- Gas Sensor

- Battery Voltage Sensing Circuit

- 16x2 LCD Display

INTRODUCTION

The Controller Area Network (CAN) is a robust vehicle communication bus standard that was primarily developed for automobile applications but has now found widespread usage in various other fields as well due to its reliability and effectiveness. It is also a key component in systems like the Real-Time CAN-Based Vehicle Monitoring System, enabling efficient and reliable data communication across vehicle components. This project focuses on developing a vehicle monitoring system utilizing the CAN protocol for monitoring and sharing vital parameters between different nodes in a vehicle. In this commentary, I will discuss the various technical aspects, features, applications, and scope of improvement for this CAN-based vehicle monitoring system.

LITERATURE REVIEW

A brief literature review regarding the history and technical evolution of CAN protocol and related research will provide useful context to understand this project. Table 1 shows the important milestones in the development of the CAN protocol. It was started in 1985 by Robert Bosch GmbH and evolved through different specifications and standardizations. Automotive manufacturers like Mercedes started adopting it in their vehicles from 1993 onwards leading to its widespread usage. Various industrial and research organizations like CAN in Automation (CiA) were formed to support and standardize it further.

Fairchild et al. in their 2002 research paper studied the temperature ranges for engine components which are relevant for the design of temperature sensors in automotive applications. Similarly, Johnson et al. 2004 published experimental data on exhaust system temperature that can reach up to 600°C requiring heat-resistant sensor materials A comparative case study by Axelsson et al. in 2003 evaluated different in-vehicle network architectures for applications like body, comfort, and infotainment systems. It presented a table indicating the suitability of various network protocols. This provides useful guidelines for selecting the right communication standard.

An overview paper by Anaetaeioe et al. in 2007 introduced the generic in-vehicle networking protocols and analyzed architectures used by leading automakers. It also presented a case study of Volvo’s CAN-based automotive network system. CO emission standards for diesel and petrol engines according to the 2010 BS IV regulations in India specify the limits that are important to know for gas sensor selection and calibration.

The above literature presents valuable industry data, research findings, and protocol evaluation studies highly relevant to this vehicle monitoring project using CAN. It helps establish the need for such systems and provides technical references.

HARDWARE DESCRIPTION

The hardware blocks used in the system include PIC microcontrollers, CAN transceivers, voltage regulators, sensors, and an LCD.

PIC Microcontrollers:

The PIC18F458 microcontrollers used have features like 12 ADC channels, 3 timers, 12 interrupts, and an inbuilt CAN module making them suitable for this application. Their low power, small size, and cost-effectiveness are additional advantages.

CAN Transceiver:

MCP2551 transceivers interface the CAN controllers with the physical bus, performing voltage level conversions between the 5V TTL logic and differential 24V bus signals. They support high-speed 1Mbps operation essential for real-time automotive use.

Voltage Regulator:

An LM7805 regulator maintains a stable 5V supply from the varying vehicle voltage for the microcontrollers and other ICs.

Sensors:

LM35 temperature, LDR, gas, and battery voltage sensing circuits interface the physical parameters to ADC pins. They have wide measurement ranges suitable for automotive use.

Display:

A 16×2 LCD is interfaced through 4 ports of a PIC for displaying the monitored parameters to the user.

The hardware components selected are well-suited for automobile applications with features like robustness, reliability, precision, and compatibility with CAN specifications. Their interfacing circuits are logically designed.

SYSTEM FUNCTIONING

The system has two nodes – one each at the engine and dashboard sides. Vital parameters like temperature, battery voltage, gas level, and ambient light intensity are sampled by the engine node using the interfaced sensors. An LCD at the dashboard displays these in real time.

When the user presses a key, the dashboard node requests data from the engine node over the CAN bus by transmitting an identifier. After a continuous real-time data transmission, the engine node sends back the sampled parameter values. This two-way communication follows the standard CAN frame formats and arbitration scheme.

The use of two microcontrollers as separate CAN nodes with distributed sensing and display ports effectively implements a monitoring network as required in automotive applications. Programming for initialization, sampling, message transfer, decoding, and display shows a good understanding of CAN protocol and microcontroller operations.

Overall, the system design, component selection, interfacing, programming, and functioning effectively demonstrate the development of a vehicle monitoring solution using the robust CAN communication protocol. It can find good applications as a low-cost prototype or extension for additional automotive parameters.

RESULTS AND PERFORMANCE

The system was simulated using Proteus and Orcad to verify correctness before hardware implementation. This is a good practice to debug design issues in software before physical assembly.

On the actual hardware, the sampled sensor outputs from the engine node like temperature, and voltage were observed to transfer reliably over the CAN bus to the dashboard display node on request. The timing of the 10-second intervals for data transfer and Arbitration of message frames followed CAN specifications successfully.

The interface circuits of sensors to ADC ports and display to microcontroller ports functioned properly with calibrated readings. Overall functionality achieved the intended monitoring application with distributed sensing and centralized display – a key requirement in automobiles.

SCOPE FOR IMPROVEMENT

While the project demonstrated successful implementation of basic vehicle monitoring using CAN, further extensions are possible:

- Additional sensors can be added for more parameters like fuel level, oil pressure, etc. to expand monitoring capabilities.

- Error detection methods specified in CAN like CRC, Bit-stuffing can be implemented for improved reliability.

- Flexible configuration of node addresses, message IDs, and trigger conditions via user interface would enhance usability.

- Protocol analysis tools can characterize performance parameters like message latency, bus loading, and error rates under different conditions.

- Advanced display interfaces using a touchscreen instead of buttons can offer a better user experience.

- Implementation of automotive-grade microcontrollers with specific CAN IP cores would improve ruggedness.

- Integration with external automotive control units can evaluate real-world applicability over extended drive cycles and environments.

Thus with continual improvements, such distributed monitoring systems have good prospects for adoption in mass production vehicles and commercial fleet management solutions.

CONCLUSION

In summary, this project has successfully designed and developed a prototype vehicle monitoring system utilizing the CAN bus-based communication between sensor nodes and display modules. The hardware and firmware implementation demonstrates the effective use of microcontrollers, sensors, and displays interfaced over the standardized CAN network for distributed automotive applications. While serving as a proof of concept, it provides a firm platform for enhancing the system with additional features. With advancements towards higher reliability, usability, and integration, such CAN networked solutions are finding increasing usage in modern automotive and industrial applications.