Summary of PRECISION CNC MOTION CONTROL UNIT ENCODER, DRIVER INTERFACE PIC16F877

The project presents a high-precision CNC motion control system using the PIC16F877 microcontroller. It involves designing a DC motor drive system with a current-regulated voltage source, incorporating a motion controller interfacing via RS232 to a PC. The system ensures accurate multi-axis motion control by integrating power modules, current regulators, and digital control implemented through assembly code in MPLAB IDE. This approach suits industrial applications needing precision and showcases iterative design improvements for enhanced performance and control.

Parts used in the CNC control circuit project:

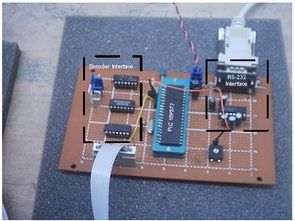

- PIC16F877 microcontroller

- DC Motor

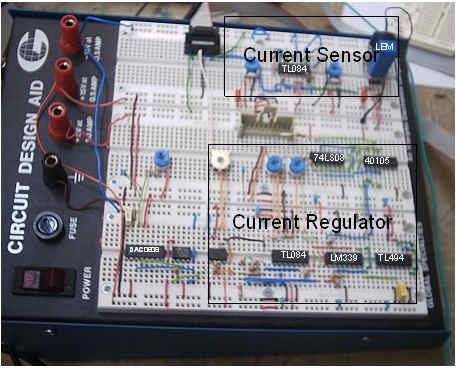

- Power module

- Current regulator

- RS232 communication interface

- Encoder

- Driver interface

- Personal Computer (PC) for control

- MPLAB IDE software (for assembly programming)

CNC control circuit PIC16F877 microcontroller used in the project’s RS232 PC connection to all floors described separately (English) source: Assembly shared MPLAB IDE software. HIGH PRECISION CNC MOTION CONTROL This thesis focuses on the… Electronics Projects, Precision CNC Motion Control Unit Encoder, Driver Interface PIC16F877 “microchip projects, microcontroller projects, pic16f877 projects, “

CNC control circuit PIC16F877 microcontroller used in the project’s RS232 PC connection to all floors described separately (English) source: Assembly shared MPLAB IDE software.

HIGH PRECISION CNC MOTION CONTROL

This thesis focuses on the design of an electrical drive system for the purpose of high precision motion control. A modern electrical drive is usually equipped with a current regulated voltage source along with powerful motion controller system utilizing one or more micro-controllers and/or digital signal processors (DSPs).

That is, the motor drive control is mostly performed by a dedicated digital-motion controller system. Such a motor drive mostly interfaces with its host processor via various serial communication protocols such as Profibus, CAN+, RS-485 etc. for the purpose of receiving commands and sending out important status/control signals. Considering that the motor drives lie at the heart of every (multi-axis) motion control system, the aim of this thesis is to explore the design and implementation of a conventional DC motor drive system suitable for most industrial applications that require precision and accuracy.

To achieve this goal, various underlying control concepts and important implementation details are rigorously investigated in this study. A low power DC motor drive system with a power module, a current regulator and a motion controller is built and tested. Several design revisions on these subsystems are made so as to improve the overall performance of the drive system itself. Consequently, important “know-how” required for building high performance (and high power) DC motor drives is gained in this research.

Source: etd.lib.metu.edu.tr CNC circuit alternative link: precision-cnc-motion-control-unit-encoder-driver-interface-pic16f877.rar