Dc servo motor control circuit PIC18 and PIC16 series micro controllers can be operated with software “C” language prepared by the software files 18F for the pic18c452 16c for the series pic16c877 used C language to be portable sebum… Electronics Projects, PICmicro PIC18 PIC16 DC Servomotor Application “microchip projects, microcontroller projects,

Dc servo motor control circuit PIC18 and PIC16 series micro controllers can be operated with software “C” language prepared by the software files 18F for the pic18c452 16c for the series pic16c877 used C language to be portable sebum with the “PIC18 PIC16 series” is called

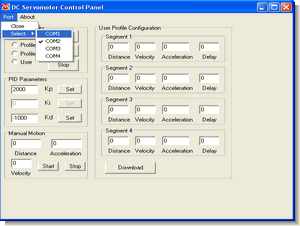

Circuit via computer software (Winservo) Please check with your communication is provided via RS232 com port

The project is one example of Microchip `s explained all the details of the source file (english) control program and C software (18motor.c, 877mot.c) have also L6203 (bridge motor driver), 24LC01, a good example for the use of DS275

PICMICRO DC SERVOMOTOR APPLICATION

INTRODUCTION:The PICmicro® microcontroller makes an ideal choice for an embedded DC Servomotor application. The PICmicro family has many devices and options for the embedded designer to choose from. Furthermore, pin compatible devices are offered in the PIC16CXXX and PIC18CXXX device families, which makes it possible to use either device in the same hardware design. This gives the designer an easy migration path, depending on the features and performance required in the application. In particular, this servomotor has been implemented on both the PIC18C452 and PIC16F877 devices, and we’ll look at the MCU resources required to support the servomotor application. With an understanding of the servomotor functions, you can start with the design shown here and implement your own custom DC servomotor application based on the PICmicro device that suits your needs.

The PICmicro MCU handles many functions in the servomotor application, such as:

• User control interface

• Measurement of motor position

• Computation of motion profile

• Computation of error signal and PID compensation algorithm

• Generation of motor drive signal

• Communication with non-volatile EEPROM memory

HARDWARE: A Pittman Inc. 9200 Series DC motor was used to develop the application source code. The motor was designed for a 24 VDC bus voltage and has a no-load speed of 6000 RPM. The torque constant (KT) for the motor is 5.17 oz-in/A and the back-EMF constant (KE) is 3.82 V/kRPM. This motor has an internal incremental encoder providing a resolution of 500 counts-perrevolution (CPR). In practice, the design should be compatible with almost any brush-DC motor fitted with an incremental encoder.

A schematic diagram for the application is shown in Figure 1. The DC motor is driven by a SGS-Thomson L6203 H-bridge driver IC that uses DMOS output devices and can deliver up to 3 A output current at supply voltages up to 52 V. The device has an internal charge pump for driving the high-side transistors and dead-time circuitry, to prevent cross-conduction of the output devices. Each side of the bridge may be driven independently and the inputs are TTL compatible. An enable input and automatic thermal shutdown are also provided. A transient voltage suppressor is connected across the motor terminals to prevent damage to the L6203.

PICmicro PIC18 PIC16 DC Servomotor Application files:

FILE DOWNLOAD LINK LIST (in TXT format): LINKS-8474.zip

Source: PICMICRO PIC18 PIC16 DC SERVOMOTOR APPLICATION