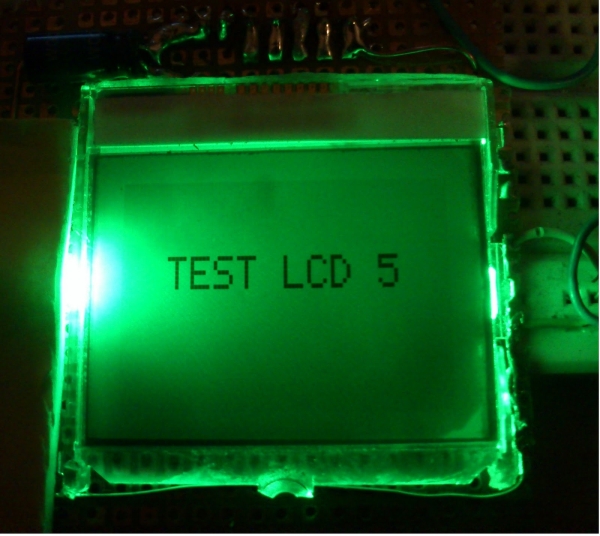

Displaying content on a normal alphanumeric display is very limited ,we have to be limited with the font size and we can’t draw any graphics also. but convention Graphics lcd are really very expensive so here is the solution, you can use Nokia 3315 / 3310 monochrome LCD to display your large font text and graphics . the reason behind using this LCD is ,it is really very cheap and can be powered with 3 volts supply. so it is really good for battery powered application.

Project Description

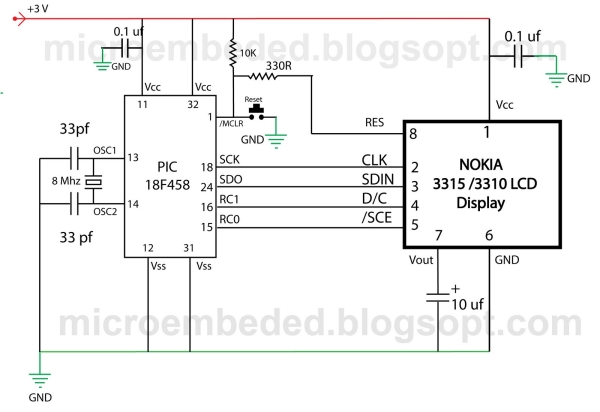

however you can use almost any microcontroller (with capability to work on 3v ) do display content on this LCD, may be that micro controller is PIC , AVR or MSP 430 , but in this demonstration we will be using Microchip PIC 18F458 Microcontroller.

About LCD:-

Nokia 3315 / 3310 Graphical LCD uses PCD8544 Controller chip From Philips. It is a chip-on glass(COG) with 8 pin connector on the back side of the LCD . You can refer to its datasheet for more information about this controller. (CLICK HERE TO DOWNLOAD PCD8544 Controller DATA SHEET).we will discuss only few main points here for out project purpose.

The typical example of RAM is shown in the figure blow, The vertical axes area addressed form 0 to 5 with eight bits for each address when combining with x axes, it can be represented as bank.

The horizontal axes are addressed form 0 to 83 and each bit will refer the corresponding pixel in X direction.

Addressing Mode

There are two type of addressing mode in this LCD

Vertical addressing Mode

A byte is sent to The LCD as follows:-

1:- Set SCE To GND

2.Set D/C to required state (Data or command)

3.Place a bit in SDIN line

4. Make high-to-low transition in CLK input.

5.Repeat step 3 and 4 for the remaining seven bits.

The initialization sequence of LCD

1. Pull SCE line to Ground to Enable The LCD.

2 Set D/C pin low to send commands to the LCD.

3. Write 0x21 Byte to LCD on the serial Bus. Here the LCD operates in Function set Command For extended instruction set.

4. Write 0xC8 Byte to LCD on the serial Bus. This set the operating voltage (Vop) of the LCD.

5. Write 0x06 Byte to LCD on the serial Bus. This set the temperature coeffcient.

6. Write 0x13 Byte To LCD on the serial Bus. This set the bias system of the LCD.

7. Write 0x20 Byte To LCD on the serial Bus. This allow the LCD to operate in function set command with basic instruction.

For more detail: Nokia 3315 3310 LCD interfacing with Microcontroller