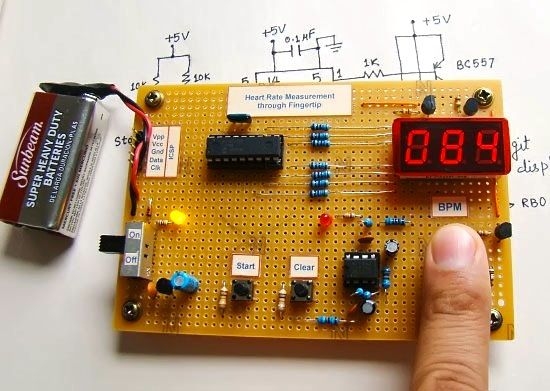

Step 1: Sensor assembly

The sensor unit consists of an infrared light-emitting-diode (IR LED) and a photo diode, placed side by side, and the fingertip is placed over the sensor assembly, as shown below. The IR LED transmits an infrared light into the fingertip, a part of which is reflected back from the blood inside the finger arteries. The photo diode senses the portion of the light that is reflected back. The intensity of reflected light depends upon the blood volume inside the fingertip. So, every time the heart beats the amount of reflected infrared light changes, which can be detected by the photo diode. With a high gain amplifier, this little alteration in the amplitude of the reflected light can be converted into a pulse.

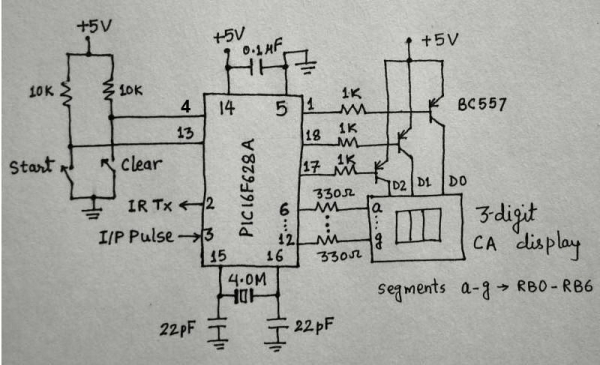

Step 2: Signal conditioning circuit

Step 2: Signal conditioning circuit

The reflected IR signal detected by the photo diode is fed to a signal conditioning circuit that filters the unwanted signals and boost the desired pulse signal. The circuit diagram above shows the IR LED (D1) and the photo diode (D2) along with the signal conditioning circuit made of two stage operational amplifiers configured as active low pass filters. The cut-off frequencies of both the filters are set to about 2.5 Hz, and so it can measure the pulse rate up to 2.5*60 = 150 bpm. The gain of each filter is about 100, which gives the total 2-stage amplification of 10000. This is good enough to convert the weak pulsating signal into a TTL pulse.

For more detail: Microcontroller measures heart rate through fingertip