Summary of LiFePO4 Charger

The article describes the creation of a dedicated USB charger for LiFePO4 AA and AAA batteries, based on Patrick Van Oosterwijck’s open-source LiFePO4wered/USB™ project. Modifications include changing the USB connector from Micro to Mini, adding a jumper to switch charging currents for AA and AAA batteries, adjusting resistor values for available parts, reducing PCB size to lower costs, and modifying the USB breakout header. The DFN-10 chip was soldered using tinning and heat gun techniques, while other components were soldered by hand. The project aims for convenient USB charging tailored to battery size.

Parts used in the LiFePO4 USB Battery Charger Project:

- DFN-10 package IC (3x3 mm)

- Mini USB connector

- Jumper connector (for charge current selection)

- Resistors (values adjusted for charge currents of 185 mA and 525 mA)

- Battery holder (for AA/AAA LiFePO4 batteries)

- PCB (custom design based on OSHW LiFePO4wered/USB™)

- USB breakout header (modified to output VUSB 5V)

since I really like using LiFePO4 AA and AAA batteries in some of my projects [1][2][3], I finally gave in and built a dedicated charger for them.

Previously I used a lab power supply to mimic the constant current/constant voltage charging curve, which worked also fine. But after seeing Patrick Van Oosterwijck nifty LiFePO4wered/USB™ [4], I thought it would be a bit more convenient to charge these batteries using USB.

* Changed the Micro-USB connector to a Mini one, because I happen to have these connectors in my parts bin, and also because I have more Mini-cables lying around.

* Replaced the solder bridging jumper pads by a regular jumper connector so I can switch between high and low charging current depending on whether I charge an AA or AAA battery.

* Changed the resistors which select the charge current to values I had readily available. (Jumper open: 185 mA for AAA batteries, jumper closed: 525 mA for AA batteries.)

* Got rid of the long PCB extension where the battery holder is soldered to reduce the PCB cost ($2.90 for three boards from OSH Park).

* Changed the USB-breakout header to contain VUSB (5V) instead of VBAT.

Soldering the 3×3 mm DFN-10 package was done by first tinning the pads, placing the chip, and then heating the board from the bottom with a heat gun. The remaining SMD parts were soldered conventionally with a regular iron.

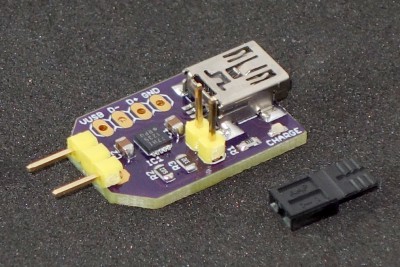

Here is a picture of it charging an AA battery:

Please find my modified EAGLE files attached.

For more detail: LiFePO4 Charger