Introduction

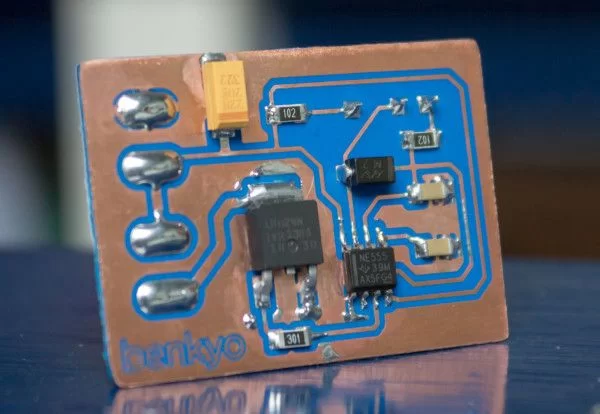

I wanted to dim my room LED lighting with a potentiometer, and decided on creating a solution from scratch to make it more fun and educative. I decided to go with the fairly well-known 555 PWM circuit. To decrease size and for learning purposes I decided on using surface-mount components for the first time. The reason I wanted to make this 555 PWM circuit is actually just to see if I could solder SMD components on home-etched PCB’s, and to see how hard it actually is.

Working with breadboards is really great, and you can very easily prototype your circuit and swap out components. However, after a while you might want something more permanent, so you grab the good old perfboard, and things get a lot more nasty, with wires sticking out everywhere. After having some experience with PCB milling, I wanted to give etching a shot. And having plenty of soldering experience, I decided on using surface-mount components.

To make soldering easier, I decided on using 1206 resistors and capacitors, except for the 22µF tantalum capacitor used for the Vcc line. Also not having a solder mask will make things a bit more messy, I had to use some external flux to make sure the solder flowed nicely.

Specifications

- Operates at roughly 1Khz

- Voltage range 5v – 30v

- 100mV ripple @ 1A

- At least 2A continuous current without heat sink on MOSFET

- Duty cycle from ~10% – ~90%

As you can see, the duty cycle is not that good. It doesn’t go fully off or on, I already saw this on the breadboard, but decided it didn’t matter because I wanted a simple circuit with average performance.

For more detail: Surface-mount 555 PWM circuit