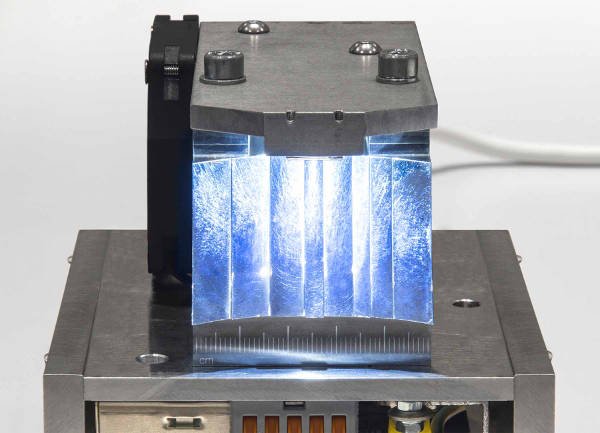

Using a single super-power LED – 1,400 lm, emitting at 200Mcd/m2 – Osram has produced a dip headlight beam in its labs.

The distribution of light indicates that car lighting standards can be met – see candela plot.

“This LED has a luminance three times that of existing versions. This means that a single LED can be used to provide a complete low beam.

It predicts these light levels should soon be achieved by production LEDs, and it predicts a low beam unit measuring 30x50mm “in only a few years”.

The die loses only 10% of intensity at 85°C, according to the firm, and is soldered directly to copper for heatsinking – which it one of the technologies borrowed from projection.

This is not the most extreme form of heatsinking used in industry – some telecoms lasers have a diamond heat spreader between die and copper.

In future headlights, Osram sees high (main) beam being produced by semiconductor laser – where a blue laser shining through phosphor produces the high luminance required – while the announced technology produces low (dip) beam. “Other automotive applications such as interior lighting and new types of head-up display will follow”, said Osram.

For more detail: Osram breaks one-LED headlamp barrier