I have been an avid electronics DIY guy for many years now, and I have spent a lot of that time struggling to learn how to make my own PCBs. I have tried every technique that I have come across on the internet, from iron-on print outs to dry photosensitive blue sheets. Sometimes I was successful in my efforts to make a passable PCB, but when it was time to reproduce those results, something would go wrong.

After a lot of attempts and frustration, I was determined to find a solution that didn’t result in me sending my files off to a PCB fab house. I use a fab house after I have tested a design on a homemade PCB. I finally found a solution where I can reproduce aesthetically pleasing PCBs by using liquid negative photo-sensitive paint. In this Instructable, I will share with you a technique that I have developed to do this.

DISCLAIMER:

Hazardous chemicals are used in this tutorial and I am not responsible if you hurt yourself. Practice caution, follow common safety guidelines at all times, and use gloves and protective eyeware.

Step 1: Supplies

Gather the supplies needed.

1. Photosensitive paint

2. Small spatula

3. Mixing jar

4. Heat plate ( optional )

5. Silicon or plastic tongs

6. Protective gloves and eye-ware

7. Copper clad board

8. Scale ( optional )

9. Plastic container for etching

10. Aquarium pump with stone diffuser and hose

11. Inverted PCB artwork printed on a laser transparency

12. Paint brush

13. Jar to put the developing solution in

14. Clear plastic or glass plates and some clips

15. Chemicals:

Hydrochloric acid (aka Muratic Acid from hardware store in the pool section or also found as a concrete cleaner)

Hydrogen peroxide

Sodium hydroxide (drain cleaner)

Sodium carbonate (aka Washing soda found next to laundry supplies)

Acetone

Step 2: Paint

I got the photosensitive paint off ebay. (Use the tag “Negative Photoresist” in your search.) The paint is very thick and needs to be diluted. Pour some of the paint into a small glass jar, add a few drops of acetone and stir with the spatula. You want it to be a little bit thinner than it was originally, but not too thin. If it’s too thin, stir it and it will get thicker as the acetone evaporates. This paint smells bad, so I recommend that you do this step outside…but not in the direct sunlight or you will ruin the paint! Do it under a car port or in the garage with the door open, making sure you have a lot of ventilation.

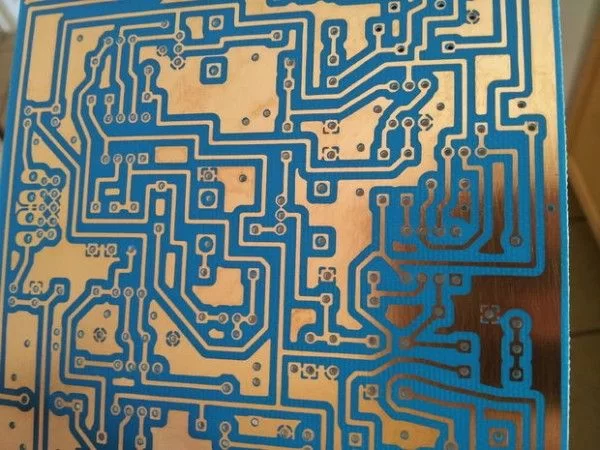

Pour a small amount of the diluted paint on your copper and use the spatula to spread it onto the board. You want to spread the paint evenly across the surface while trying not to leave any thin areas of paint. This can be tricky and takes practice. Initially, I tried a paint brush but it left streaks that were hard to remove. I got much better results with a spatula.

Next, you need to let the board dry out. This takes a while and I found that I could speed up the process by placing the board on a heat plate overnight. I used an old coffee maker that was about to be thrown out before I realized that it could be repurposed as a heat plate. I simply cut off the top portion off the coffee maker with a hand saw. I had an aluminum plate lying around, so I placed it on heat plate, put the freshly painted board on top and then put the whole thing in a dark shed, where I let it set overnight.

If you’re starting to think that this process is going to take too long, remember that if you want quality results, patience pays off here. You have to take your time – rushing this will lead to problems. While you don’t have to use a heat plate and can simply let the painted copper sit in the dark, it will take even longer to dry out.

For more detail: DIY PCB using Liquid Photoresist