When I started my career in control systems I was fascinated with the many different ways that machines could be interfaced to the environment they operated in. Limit switches (electrical and optical), encoders, resolvers, strain gauges, thermocouples…

the control system engineer had a long list of sensors to choose from. And the list has grown even longer following successful innovations in micro machining. Today the sensor and conditioning electronics, and even a microprocessor for signal processing, are integrated on a chip. Sensor integration has helped make machine control systems smaller and easily distributed throughout a given process. But they have also obscured what actually goes on inside the black box. As a design engineer, I enjoyed reading schematics and taking sensors apart to figure out how they did what they did. I learned quite a bit about how noisy and stressful the outside world is on sensitive electronics, and how challenging it can be to reliably separate out a desired signal from industrial background noise.

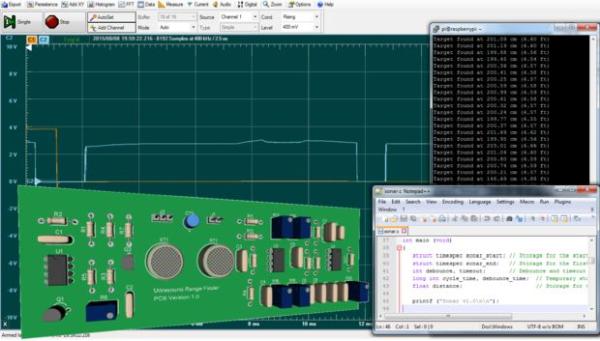

At first glance, the theory behind an ultrasound range finder seemed intuitive and there were a number of small and inexpensive ultrasound sensors available commercially. But all of these are highly integrated mixed-signal products that would have been difficult to fully understand and experiment with using an oscilloscope and pulse generator. So I decided to design my own and see how ultrasonic waves propagate, reflect, and interfere in a given space.

For more detail: Analog Ultrasound Range Finder