I’ve had good cause to be reading and perusing a few old Circuit Cellar articles every day for the past several weeks. We’re preparing the upcoming 25th anniversary issue of Circuit Cellar, and part of the process is reviewing the company’s archives back to the first issue. As I read through Circuit Cellar 143 (2002) the other day I thought, why wait until the end of the year to expose our readers to such intriguing articles? Since joining Elektor International Media in 2009, thousands of engineers and students across the globe have become familiar with our magazine, and most of them are unfamiliar with the early articles. It was in those articles that engineers set the foundation for the development of today’s embedded technologies.

Over the next few months, I will highlight some past articles here on CircuitCellar.com as well as in our print magazine. I encourage long-time readers to revisit these articles and projects and reflect on their past and present use values. Newer readers should not regard them as simply historical documents detailing outdated technologies. Not only did the technologies covered lead to the high-level engineering you do today, many of those technologies are still in use.

The article below is about Thomas Black’s “BatMon” battery monitor for RC applications (Circuit Cellar 143, 2002). I am leading with it simply because it was one of the first I worked on.

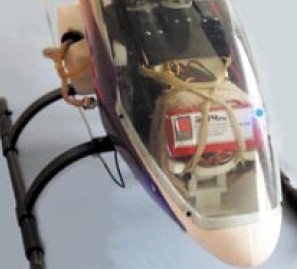

For years, hobbyists have relied on voltmeters and guesswork to monitor the storage capacity of battery packs for RC models. Black’s precise high-tech battery monitor is small enough to be mounted in the cockpit of an RC model helicopter. Black writes:

I hate to see folks suffer with old-fashioned remedies. After three decades of such anguish, I decided that enough is enough. So what am I talking about? Well, my focus for today’s pain relief is related to monitoring the battery packs used in RC models. The cure comes as BatMon, the sophisticated battery monitoring accessory shown in Photo 1.

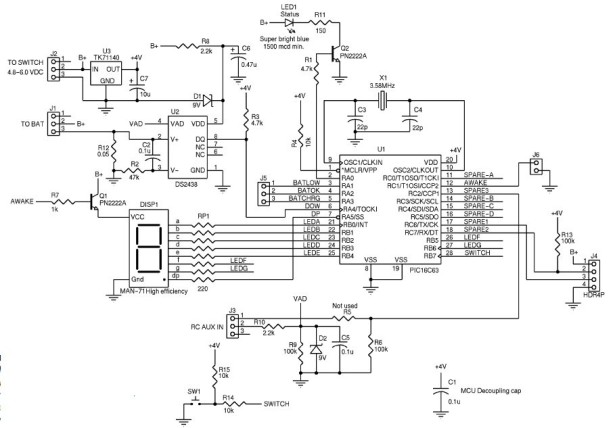

Today, electric model hobbyists use the digital watt-meter devices, but they are designed to monitor the heavy currents consumed by electric motors. I wanted finer resolution so I could use it with my RC receiver and servos. With that in mind, a couple of years ago, I convinced my firm that we should tackle this challenge…My solution evolved into the BatMon, a standalone device that can mount in each model aircraft (see Figure 1).

This is not your typical larger-than-life Gotham City solution. It’s only 1.3″ × 2.8″ and weighs one ounce. But the BatMon does have the typical dual persona expected of a super hero. For user simplicity, it reports battery capacity as a zero to nine (0% to 90%) level value. This is my favorite mode because it works just like a car’s gas gauge.

For more detail: DIY, Microcontroller-Based Battery Monitor for RC Aircraft