When it comes to PCBs, there are certainly a wide variety of them in the current market.

Designed for a host of different requirements and needs, a vast array of them exists for every imaginable application that one could conceive.

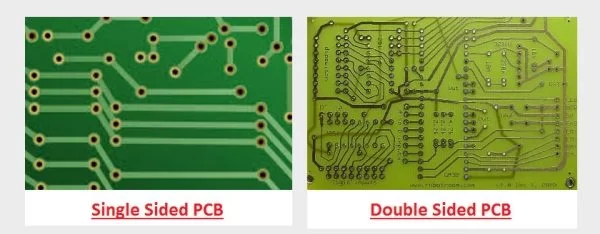

Of the many such variants that exist, PCBs and their designs can be narrowed down to two variants, namely single and multi layers.

Although much can be said about the two, a summary of their design can help one to get a better understanding about their nature and function.

When it comes to single-layer PCBs, which are also referred to as single-sided PCBs, they are as the name would suggest the PCBs which have the components on one side of the board, while the circuitry lies on another.

Multi-layered PCBs, or multi-sided PCBs, are very similar to the single-sided ones, except that they have two side-traces, with a top and bottom layer, meaning that both sides can be used for the creation of circuits. It helps in the creation of complex and high density circuits, without the need for any point-to-point soldering.

THE FACTORS FOR CONSIDIERATION

When it comes to actually picking out an ideal PCB, whether single or multi-layered ones, there are a few things that need to be taken into account.

There is much that can be said about getting the right PCB for the job, the details of which are given below.

Given in the points below, are some of the key considerations that are taken into account. Some of them are general in nature, while others are more specific.

1.) Cost Factor

By far, one of the main considerations when it comes to the use of picking a PCB is the cost.

Regardless of the requirement, there is a need for one to have the same work within one’s budget. This holds true regardless of one’s requirements at the end of the day, for all applications.

Specifically, when it comes to cost, the PCBs on the low end, are the single-sided ones, given their simplicity and ease of construction. The more expensive on the other hand, are the dual-sided ones, which tend to have a higher cost given their complexity of design.

2.) Time Constraints

This time constraint here has to do with the amount of time that the client has, to get a product out.

Given that all clients and suppliers are operating on tight deadlines, time is of the utmost essence in the product life cycle. This means that everything is often planned in advance, from the beginning of the product design, to the time when it is set to hit the market shelf.

With regard to the time constraint, those with a short amount of time to spare would do well with single-sided PCBs, given their ease of design and construction. The multi-sided ones on the other hand, are meant for those who have more time on their hand, and wouldn’t mind waiting a bit longer to get the final delivery.

3.) Nature of the Product Requirement

The product requirement is another consideration that is to be taken into account.

The nature of the requirement will play a major role in determining the kind of PCB to be used, as well as individual variations.

For those applications where the processing and other systemic requirements are simple and light, a single-sided PCB would do fine. Requirements for more intense and complex necessities on the other hand, would necessitate the use of multi-sided PCBs, given that they are designed for such a purpose.

4.) Product Miniaturization

Quite often, there is a need to make a product smaller or more compact in nature.

A good example of this is that of hand-held devices, where gadgets that once took up a large amount of space, are made to occupy a lesser amount of space, without compromising on its capacity or features.

Should there be a need to reduce the size of a gadget, the use of multi-sided PCBs is ideal, as they allow for complex and high-density designs.

5.) Production Volume

Another aspect of the selection process would be that of the production volume, or the amount of PCBs needed for any particular project.

When it comes to production volume, or the amount of units that can be manufactured in a given time period, single-sided PCBs are ideal, as their simple design and nature of construction makes it easy to scale up rapidly, allowing for large quantities of them to be produced.

This however, is not usually possible in the case of multi-sided PCBs, which take considerably greater amount of time to manufacture, especially when it comes to doing so in large volumes.

6.) Reliability & Quality

In general, one should expect to find manufacturers, who are can manufacture PCBs that are both reliable and of quality construction, and preferably with credentials to prove it.

As for the boards themselves, multi-layered PCBs are an ideal when quality is of concern, in comparison to single-layered ones. It is due to the fact that multi-layered ones, given their complex design, tend to be made with greater attention to detail. Since there are several different ways that things can go wrong, more attention and care is given during and through the design process, so as to prevent the possibility of something going wrong.

While the quality aspect is taken into consideration for single-sided PCBs as well, it is generally a lot less, given that the simple design is often seen as a hedge against potential design flaws seen as a hedge against potential design flaws. Visit Victory PCB.

7.) Durability

Durability refers to the fact that some of the boards are more long-lasting than others.

And this can be a major issue, when designing quality applications, with considerable product lifespan.

If durability is of concern, multi-layered PCBs make for ideal choices, given that they are generally thicker and well-designed than single-layered PCBs.

8.) PCB Inspection

Although clients generally verify the quality of the PCBs, there is a little more to it than just checking the quality of the construction.

Single-layer PCBs do not require much inspection, given their simple construction. Multi-layer PCBs on the other hand, would require much more thorough inspection, given that they have a complex design structure, complete with other components, making it possible for the same to go wrong in a multitude of ways.

9.) Company Profile & Infrastructure

Last but not the least, getting a suitable company is another great thing to look into, when getting the right PCB.

From the right manufacturing equipment and facilities to a track record of performance, all of it will play a key role in ensuring quality shipments for one’s production needs.

Likewise, a great customer care service offered by the company would add to the advantage as a suitable manufacturer, given that there is every chance of issues cropping up after the shipments of the final product has been completed.

As a whole, the points mentioned above should prove to be of help, when it comes to making the right choice between PCBs.

Regardless of whether you go for single-layer PCB or multilayered ones, it should be a bit more workable, when you finally get started with deciding the ideal variant for your technological need.

Other related readings about multilayer PCB: One-Stop Multilayer PCB