Thermal Conductivity: A measure of the ability of a material to transfer heat. Given two surfaces on either side of a material with a temperature difference between them, the thermal conductivity is the heat energy transferred per unit time and per unit surface area, divided by the temperature difference 1.

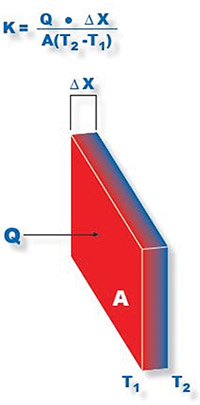

Thermal conductivity is a bulk property that describes the ability of a material to transfer heat. In the equation in Figure 1, thermal conductivity is the proportionality factor K. The distance of heat transfer is defined as rate of heat transferred through the material (Q), from temperature T1 to temperature T2, when T1>T2 2.

Figure 1: Conduction heat transfer process from hot (T1) to cold (T2) surfaces.

Thermal conductivity of materials plays a significant role in the cooling of electronics equipment; from the die where the heat is generated to the cabinet where the electronics are housed, conduction heat transfer and, subsequently, thermal conductivity, are the integral components of the overall thermal management process.

The path of heat from the die to the outside environment is a complicated process that must be understood when designing a thermal solution. In the past, many devices were able to operate without requiring an external cooling device like a heatsink. In these devices, the conduction resistance from the die to the board needed to be optimized, as the primary heat transfer path was into the PCB. As power levels increased, heat transfer solely into the board became inadequate. Much of the heat is now dissipated directly into the environment through the top surface of the component. In these new higher-powered devices, low junction-to-case resistance is important, as is the design of the attached heatsink.

To determine the importance of material thermal conductivity in a specific thermal management application (e.g. a heatsink), it is important to separate the overall thermal resistance associated with conduction heat transfer into three parts: interfacial, spreading, and conduction resistances.

Interface Material

An interface material enhances the thermal contact between imperfect mating surfaces. A highly thermally conductive material, with good surface wetting ability, will reduce interfacial resistance.

Spreading Resistance

Spreading resistance is used to describe the thermal resistance associated with a small heat source coupled to a larger heatsink. Among other factors, the thermal conductivity of the base of the heatsink directly impacts spreading resistance.

Conduction Resistance

Conduction resistance is a measure of the internal thermal resistance in a heatsink as heat travels from the base to the fins, where it dissipates into the environment. In regard to heatsink design, conduction resistance is less important in natural convection and low air flow conditions, becoming more important as flow rates increase.

For more detail: Thermal Conductivity: What is it and Why You Should Care