Hi everyone,

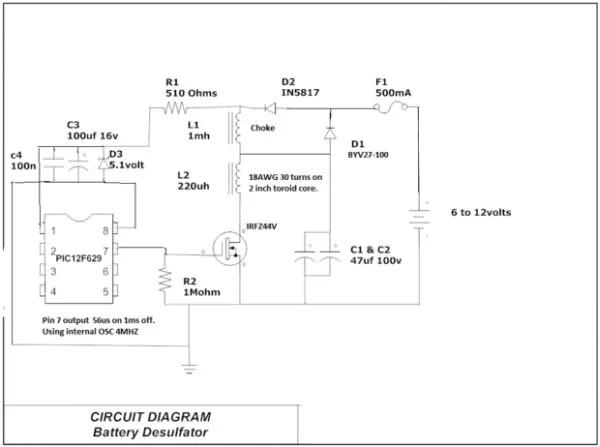

After reading so many articles on Battery desulfator i’ve decided to come out with my version of Battery desulfator using

Microchip base micro-controller using PIC12F629 or PIC 12F675.

“Please pardon my english” .I don’t really have time to check for minor grammatical errors.

Before we begin this circuit although simple in design requires DIY builders to have at least basic PIC programming knowledge with electronics.

Honestly i had no programming knowledge initially.I started on my own on how to blink led using Pic micro-controller.

I have used this circuit i design to recover 5 Maintenance –free battery ranging from 12volts 2AH (UPS battery) to 7.2AH (Previously used in electric bicycle).I have not attempted to recover a CAR battery since i don’t have any old battery in my home.

I have recovered battery eg:2AH which had voltage as low as 0.9v which i have not charged for around 8 years after removing battery from a defective home UPS.

I have managed to recover 4 12v 7.2AH battery which i have not charged since 2004.These batteries were in my self assembled electric bicycle years ago.

These batteries were all recovered in within 48hours.For a car battery it would take weeks maybe.

Battery desulfator circuit i used while with charging battery with 12volt 500ma transformer.

I’d believe using slow and steady approach do produce better result most of the time.

The frequency output from Pin 7 is 56us on with 1ms off in a infinite loop.

During programming i have set it to use internal 4MHZ PIC oscillator which have 1% tolerance and i have disabled reset /mclr.

There is only 3 connection to pic.

I noted the current consumption of the desulfator circuit is around 13 to 15mA with a well desulfated battery if connected to the charger with voltage around 13.8volts.

I noted if a old battery needs to be desulfated the voltage would increase up to 17.xx volts on battery with desulfator circuit consuming about 40 to 50mA.

The D1 diode i used is the fastest recovery diode i could find with 25ns response time.

The purpose of D2 is to prevent accidental polarity reverse at the input to protect the circuit.D2 could be replace with higher amp rating like IN5820 if needed.

It’s better to obtain C1&C2 capacitor which have a low ESR rating with at least 50V.

For L2 toroid if you could get anything from 170uh to 220uh would be sufficient.Please do not wind higher than 30 turns as the resistance would increase and hence lower the circuit efficiency as well.To be honest i don’t know the uH rating for my self made toroid but i got results which what matters in the end.

For the mosfet if you could find a lower turn on resistance with low turn on/off delays which will definitely improve the efficiency of the circuit.

I have connected a piezo speaker temporarily to old battery which needs to be charged since it would have higher internal-resistance.i noticed the piezo speaker would emit a loud 1KHZ sound.But if the battery is already well desulfated i noticed the piezo speaker connected temporarily to battery would hardly emit any sound at all.

We could use piezo speaker as a quick way to test to know if battery to be charged is well desulfated or internal resistance of the batery is already being lowered.

Source : PIC12F629 Lead-Acid Battery Desulfator