The wearables market is booming. Statistics aggregator web portal Statista, notes that the global market will be worth over $7 billion this year and $12.6 billion by 2018.

Although the potential rewards are high, this is not an easy market to enter. Designing smart watches or fitness bracelets is tough; consumers expect lots of functionality, smartphone connectivity, compact form-factor, light weight, and long battery life. The introduction of highly integrated, ultra-low-power microprocessors and wireless chips has eased the design process, but squeezing out all of the battery’s power remains key to a wearable product’s success.

This article takes a look at how silicon vendors help wearables designers extend battery life by offering power-frugal displays, microcontrollers (MCU), silicon radios, and power-management chips designed specifically for ultra-low-power applications.

Convergence of technology

Wearables have sprung to the fore because of the convergence of three key technologies1. Ultra-low-power chips that can run from watch batteries allow companies to offer compact products which, thanks to smartphone-compatible wireless technology such as Bluetooth Smart (also known as Bluetooth low energy), communicate seamlessly with smartphones and tablets. A range of inexpensive apps presents the information gleaned from the wearable in a user-friendly format indicating, for example, how long the user needs to exercise to lose weight. A recent leading-edge wearable is adidas’ Fit Smart wristband tracker which incorporates Bluetooth Smart technology from Nordic Semiconductor (Figure 1).

Figure 1: adidas’ Fit Smart is typical of the latest generation of wearable products. (Courtesy of adidas/Nordic Semiconductor)

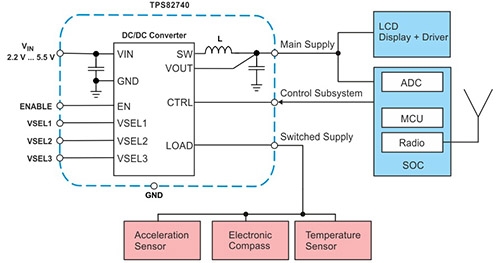

Products such as the Fit Smart combine multiple facets of engineering including advanced electronics such as 32-bit MCUs, 2.4 GHz silicon radios, analog-to-digital converters (ADC), and display drivers. In addition, a wearable could incorporate several sensors measuring atmospheric pressure, humidity, temperature, and acceleration. The capability of the MCU significantly affects the performance of the device and determines its market appeal; the MCU also often integrates other elements of the wearable’s electronics such as the Bluetooth Smart radio and the ADC. However, that’s not the whole story.

Wearables must be unobtrusive; that places constraints on size and weight and, in turn, on the capacity of the power source. Some wearables, such as smart watches with powerful computation capabilities and GPS, will be designed to draw on the resources of rechargeable Li-ion batteries and consumers accept the requirement to top up the cell occasionally. However, if the frequency of recharges can be reduced the product may gain an edge over a competitor.

Other wearables, such as fitness bracelets, are expected to run for months without cell changes. Technologies such as ARM-based low-power embedded processors or optimized microcontrollers such as Texas Instruments’ (TI) MSP430 and “ultra-low-power” wireless connectivity such as Bluetooth Smart, RF4CE, or ZigBee help engineers design devices that can run tiny batteries such as CR2032 coin cells. For this type of battery to last several months, average current draw must be limited to just a few milliamps. That restricts a product to perhaps a few tens of milliamps when operating normally and tens of microamps or even a few hundred nanoamps when in sleep mode (see the TechZone article “Tiny Voltage Regulators Meet Wearable Electronics Space Constraint.”).

Designing for low power

The display (if one is fitted), MCU, and silicon radio are responsible for the majority of the power draw in a wearable device. Manufacturers attempt to limit the display-power consumption by using technologies such as organic LED (OLED) displays. OLEDs consume less power than conventional LEDs because they do not need any backlighting. The technology also lends itself to thinner and lighter displays (see the TechZone article “OLEDs Move Closer to Mainstream Lighting”). To save even more power, these displays present minimal information because the consumer is typically able to retrieve lots of statistics from an associate app on their smartphone, and the displays switch to power-saving modes quickly when not being accessed.

The MCU in a wearable needs to deal with some heavy computational work while minimizing power consumption. Fortunately, silicon vendors have lots of experience in optimizing this trade-off in mobile devices such as cellphones and mp3 players. Techniques such as high-clocking rates to get the work done quickly and allow the MCU to return rapidly to a low-power sleep state minimize static power losses and extend battery life (see the TechZone article “Design Techniques for Extending Li-Ion Battery Life”).

For more detail: Extending Battery Life in Wearable Designs