The percentage of water present in the air is termed as humidity. Water as gaseous state called vapor. As the temperature of the air increases more water vapor can be generate.

Humidity measurement in industries is critical because it may affect the business cost of the product and the health and safety of the personnel. So, its huge importance of humidity sensor is very important, especially in the control systems for industrial processes like chemical gas purification, dryers, ovens, film desiccation, paper and textile production, and food processing. In agriculture, measurement of humidity is important for plantation protection (green house), soil moisture monitoring, etc.

Types of humidity:—

1) Relative Humidity = (density of water vapor / density of water vapor at saturation) x 100%

2) Absolute=Mass(vapour) / volume. Unit-grams/m3

3) Specific:Mass(vapour) / total mass.

4) Dew Point:Temperature(above 0°C) at which the water vapor in a gas condenses to liquid water)

5) Frost POINT: Temperature(below 0°C) at which the water vapor in a gas condenses to ice

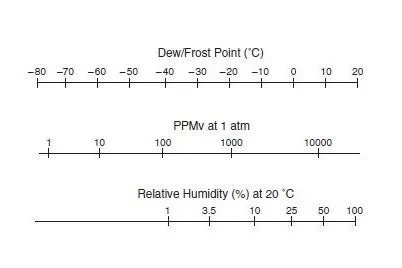

Most Common:

- Relative Humidity (RH),

- Dew/Frost point (D/F PT) and

- Parts Per Million (PPM) are used.

RH is a function of temperature, and thus it is a relative measurement.

Dew/Frost point is a function of the pressure of the gas but is independent of temperature and is defined as absolute humidity measurement.

PPM is also an absolute measurement.

Step 1: Working of Humidity Sensor

Most humidity sensors use capacitive measurement to determine the amount of moisture in the air.

This type of measurement relies on two electrical conductors with a non-conductive polymer film laying between them to create an electrical field between them. Moisture from the air collects on the film and causes changes in the voltage levels between the two plates. This change is then converted into a digital measurement of the air’s relative humidity after taking the air temperature into account. Above figure can clear your doubt.

DHT11 Technical Specifications:

Humidity Range: 20-90% RH

Humidity Accuracy: ±5%RH Temperature Range: 0-50 °C Temperature Accuracy: ±2% °C Operating Voltage: 3V to 5.5V

The DHT11 calculates relative humidity by measuring the electrical resistance between two electrodes.

The humidity sensing component of the DHT11 is a moisture holding substrate with the electrodes applied to the surface. When water vapor is absorbed by the substrate, ions are released by the substrate which increases the conductivity between the electrodes. The change in resistance between the two electrodes is proportional to the relative humidity. Higher relative humidity decreases the resistance between the electrodes while lower relative humidity increases the resistance between the electrodes.

The DHT11 converts the resistance measurement to relative humidity on an chip mounted to the back of the unit and transmits the humidity and temperature readings directly to the Arduino Nano.

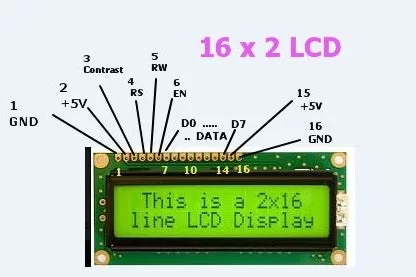

Step 2: Circuit-Diagram of Sensor(DHT11) With Atmega32 and LCD

Connect as links given in diagram.

The above circuit diagram shows interfacing of ATmega32 to DHT11 sensor.

In that, DHT11 sensor is connected to PD6 (Pin no. 20)

Source: Digital humidity sensor using PIC microcontroller